CAMX 2021 exhibitor preview: AGC Chemicals

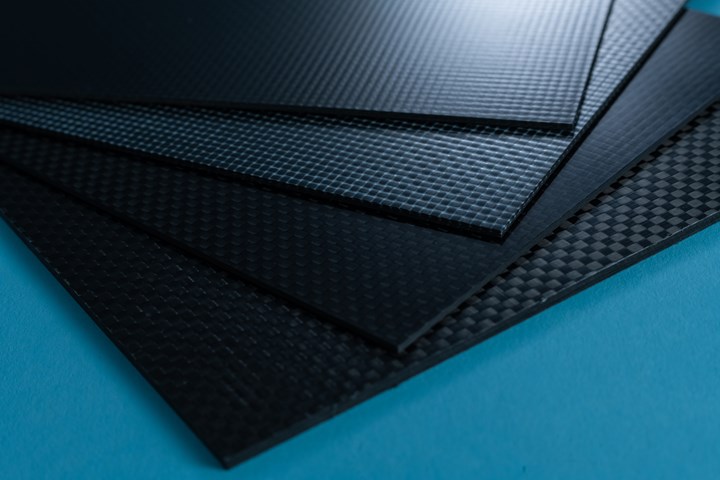

AGC Chemicals’ Fluon+ fluoropolymers are ideal for composites applications that require a durable, lightweight material, such as automobiles, aircraft and sports products.

AGC Chemicals Americas Inc. (Exton, Pa., U.S.) introduces Fluon+ functionalized fluoropolymers that reportedly enhance the performance of carbon fiber-reinforced thermoplastic (CFRP & CFRTP) composites. These compounds are ideal for composites applications that require a durable, lightweight material, such as automobiles, aircraft and sports products, as well as printed circuit boards requiring low transmission loss and high heat resistance.

AGC says the performance benefits of these compounds include:

- Wide temperature range (-200°C up to 260°C)

- Impact strength

- Vibration damping

- Near-zero water absorption

- High-temperature adhesion

- Flame retardancy

- Reduced micro-cracking

- Prevention of galvanic corrosion

- Superior chemical resistance

- Excellent dielectric properties

- Low-friction surface.

AGC’s fluoropolymer-modified polyether ether ketone (mPEEK) can be used to produce different geometries such as sheets, rods, tubes, gears, liners, wire and cable insulations and films that withstand demanding operational conditions. According to AGC, the compound improves processability via extrusion molding, injection molding and compression molding. It also demonstrates a lower dielectric constant than standard PEEK at high temperatures up to 260°C.

In addition, AGC’s fluoropolymer-modified polyphenylene sulfide (mPPS) can be used to produce films, bearings, bushings, hoses and other flexible tubing and liners for chemical processing in oil and gas. AGC says it is ideal for applications that require high-temperature (>200°C) and chemical resistance, as well as retained performance.

Related Content

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Daher CARAC TP project advances thermoplastic composites certification approach

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.