Cold cutting equipment designed for carbon fiber

CAMX 2024: Sheffield, a producer of highly accurate cutting machines, highlights its C-503 model machine made to cut carbon fiber, fiberglass and even natural fibers.

Share

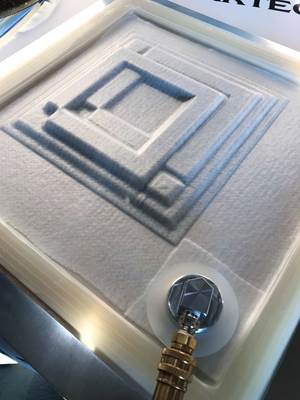

Sheffield Cutting Equipment (El Cajon, Calif., U.S.) develops and manufactures more than 80 different types and variations of highly accurate cutting machines, including specialized machines for cutting carbon fiber, as well as slitting machines. The company is exhibiting a few of its cold cutting equipment live for attendees, including its C-503 model, which is made specifically to cut carbon fiber from a roll.

Sheffield reports that its cutting equipment is used to cut 90% of all seat belts in North America for automotive and the airline industry. It also manufacturers custom machines for fall protection, medical and the U.S. military.

The C-503 model offers an adjustable feeding speed up to 14" per sec. Gear-driven rollers help maintain tolerances of ±0.001% of total length, and there are four settings to measure in inches and mm. The machine is capable of cutting from 1/16" to 300' in length with a 9"-wide knife. In addition to cutting carbon fiber, it can also process fiberglass and natural fibers like cotton.

Using this equipment is meant to automate the labor-intensive job of manually cutting materials. The operator simply installs a roll of material on the roll stand that comes with the machine, selects the quantity and length of each piece, presses the start button and can walk away from the machine. When the counter reaches the set quantity, the machine automatically stops and a beeper comes on to let the operator know that it has finished.

Related Content

-

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

-

Raw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.

-

New brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

Related Content

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreRaw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.

Read MoreNew brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

Read MoreReusable vacuum bagging solutions for composite applications

CAMX 2023: Smartech underscores its industrial reusable vacuum bagging products for reduced waste, easy debulking and the capability to be used for complex projects.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read More