Composites equipment tailored to efficiency, productivity

CAMX 2024: Engineering Technology Corp. displays a range of products for composite part manufacturers, including tape wrapping machinery, automated workcells, winding software, tensioning creels, resin baths and more.

Share

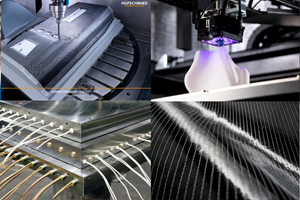

Engineering Technology Corp. (ETC, Salt Lake City, Utah, U.S.) is showcasing its latest advancements in composites technology and manufacturing solutions tailored to the needs of composite part manufacturers. The solutions include high-speed filament winding and tape wrapping machinery, automated workcells, towpreg and slit tape winding equipment, integrated robotic solutions, winding software, tensioning creels, resin baths and more.

In addition to its standard lineup of filament winders, ETC is introducing a line of standard tape wrappers specifically designed for the aerospace sector. ETC’s tape wrappers are said to enhance efficiency and reduce operator involvement in producing tapered and conical carbon fiber/phenolic structures. This equipment optimizes operational efficiency and user-friendly operation, prioritizing functionality and ease of use.

The high-speed filament winding machinery is engineered to meet the demands of modern composite part production, offerinf precision and reliability. Automated workcells and integrated robotic solutions streamline manufacturing processes, which can improve productivity and consistency. Towpreg and slit tape winding equipment provide advanced capabilities for creating high-performance composite materials, while ETC’s specialized winding software enables optimal performance and ease of use.

Tensioning creels and resin baths are designed to support efficient and consistent material handling, which is said to contribute to the overall effectiveness of the manufacturing process. These components are crucial for maintaining the integrity and quality of composite parts during production, according to the company.

For a more comprehensive look at solutions that will be at the show, view this link.

Related Content

-

Raw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.

-

CAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

-

VIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

Related Content

Raw materials distributor provides quality fiberglass, resin variety

CAMX 2024: Imate Composites presents a variety of resins, fiberglass and roving products, as well as mats and catalysts.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreVIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

Read MoreVIDEO: High-rate composites production for aerospace

Westlake Epoxy’s process on display at CAMX 2024 reduces cycle time from hours to just 15 minutes.

Read MoreRead Next

Engineering Technology (Entec) revamps filament winding machinery lineup

Engineering Technology Corp. has reorganized its line of filament winding equipment into primary products, each offering different combinations of maximum mandrel weight, maximum mandrel length, mandrel diameter, number of spindles, number of axes and speed.

Read MoreEngineering Technology launches servo tensioner for filament winding

The ST2 system, tested with pitch carbon fiber and alumina fiber, enables high-speed wet, dry and towpreg winding.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read More