Electronics

Plasma moves beyond improved bonding to coatings, multifunctional composites

Plasmatreat cold plasma systems clean, activate surfaces and apply nanocoatings for dielectric barriers and more.

WatchComposites end markets: Electronics (2025)

Electronic and smart device innovations achieved through the use of advanced materials ranging from thermoplastic composites to biomaterials emphasize high-volume production and sustainability.

Read MoreExel secures design patent extension for pultruded fiberglass radomes

Technique for antenna radomes forms “functional zones” inside composite material, enhancing existing 5G technology performance, application potential.

Read MoreTeijin lightweight materials enable VAIO portable displays

Teijin's Tenax TPCL and Panlite Sheet materials allow for the creation of complex, three-dimensional shapes in a single molding step.

Read MoreAviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

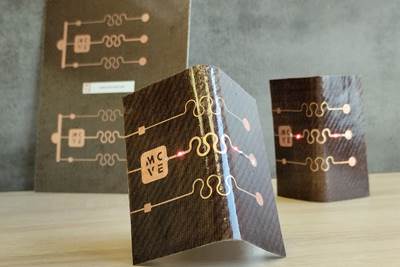

Read MoreMCVE 3DFlaxtronics enables functional composites for printed electronics

The novel process produces intelligent, highly functional films embedded in flax fiber organosheets with a bio-sourced PA 10-10 resin to advance electronic parts and components development.

Read MoreCarbon Mobile carbon fiber powers handheld gaming platform

HyRECM technology effectively stabilizes carbon fiber’s electrical and antenna properties, enabling development of next-gen electronics, such as the Snapdragon G3x Gen 2.

Read MoreSyensqo launches Swyft-Ply brand for electronics, smart devices

Multifunctional composites leverage traditional advanced material benefits while meeting specific industry manufacturing and performance requirements.

Read MoreCarbon Mobile, SABIC to develop, deploy advanced carbon fiber in connected devices

Collaboration aims to deliver the next generation of thinner, lighter, stronger and more sustainable composite materials used in consumer electronics and automotive industries.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read More