Generative Orthoses project to reshape orthopedic care

CRP Technology, MHOX and Istituto Ortopedico Rizzoli, one of the winners of the WORTH Partnership Project II, have developed bespoke orthoses using generative design, Windform GT fiberglass materials and PBF.

CRP Technology (Modena, Italy) and MHOX Design, a design research group with a focus on generative design and 3D printing, in collaboration with Istituto Ortopedico Rizzoli (IOR, Bologna, Italy), are one of 69 winning projects under the WORTH Partnership Project II 3rd Call. The project, Generative Orthoses, was awarded for its use of additive technologies and high-performance composite materials to reshape orthopedic care.

The WORTH II 3rd Call saw record-breaking participation, with 142 applications and 320 applicants from 34 EU-COSME-associated countries. After a rigorous evaluation process, 69 projects were selected for funding, featuring 158 partners from 25 countries across Europe.

Over the past 8 years, MHOX, CRP Technology and Istituto Ortopedico Rizzoli have worked together to develop high-performance bespoke orthoses using body scanning, 3D digital design, CRP Technology’s glass fiber-reinforced Windform GT composite material and the additive powder bed fusion (PBF) process. The project incorporates biomimetic design and advanced manufacturing techniques, improving both form and function while providing essential support, rehabilitation and postural correction.

Using 3D printing in generative orthotics involves several major phases:

- Scanning of the patient’s limb

- Generating the 3D model of the orthosis

- Construction of the orthosis using Windform materials and additive manufacturing.

MHOX Design handled the first two stages by developing and using software designed for the automated management of systems for mass product customization.

The procedure requires the digital uploading of the patient’s limb that the orthosis is to fit, using scanning processes based mainly on infrared technology or structured light. The scanning process takes place directly at the doctor, thanks to the portability of the sensor and its plug-and-play features.

Notably, generative design techniques and its simulation of biological phenomena make it possible to reproduce the shape of the orthosis and customize it to fit the patient’s body for subsequent 3D printing. This has led to cost and time reduction, MHOX notes, and the final result mirrors the affected limb without the need for invasive medical examinations.

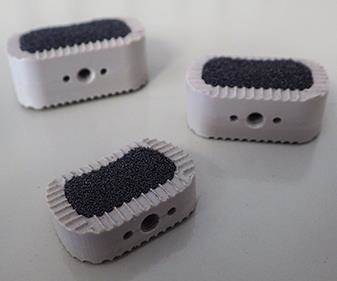

CRP Technology used Windform GT, a glass fiber-reinforced polyamide for orthoses production. Its elasticity, impermeability and durability, as well as its ability to flex for extended period of time without the risk of damage made it ideal for this type of application. In addition, Windform GT’s strength-to-weight ratio and dimensional stability ensure that the orthotic devices remain lightweight and durable while also being suitable for direct contact with the skin, as it is a skin-proof material.

CRP notes that the use of PBF is also significant, not just in terms of production speed, product performance and fit, and customization, but also regarding aesthetics for the user.

All developed orthosis solutions have been subjected to a series of tests to assess their performance. The experimentation stage studied static mode, static mode applied to the patient and dynamic mode on the patient. The results have confirmed this new application for Windform materials and technology.

CRP Technology’s research into the manufacturing of generative orthotics has been met with great interest by industry professionals. The same method of construction can be used to make orthoses for upper and lower limbs, plaster casts and prosthetic fairings. CRP Technology and MHOX Design are working alongside professional physical therapists and rehabilitation specialists to investigate the construction of solutions for patients with peroneal nerve dysfunction, resulting in drop foot further to injury, leading to a “slapping” gait.

Looking forward, CRP Technology, MHOX and Istituto Ortopedico Rizzoli continue to refine and automate the design processes, ensuring that the production of fully customized orthotic devices becomes scalable and market-ready for a broader patient base.

Related Content

Composite innovations feature automotive, water sports, UAV and consumer project versatility

JEC World 2025: Precision, performance and reliability are at the core of Cobra International’s display, involving a front end, portfolio of water sports applications, a fixed wing drone and more.

Read MorePost Cure: Natural mineral fiber biocomposite via AFP enhances implant integration

Arctic Biomaterials produces high-quality composite biomaterials incorporating a natural mineral fiber that is useful in medical and healthcare-related fields.

Read MoreComposite combat drone inlet duct proves novel fabrication approach

The 30-foot overbraided Frankenstein demonstrator was designed by NIAR, A&P and Fiber Dynamics to explore more flexible manufacturing of complex composite structures.

Read MoreFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreRead Next

Orthopedics: Carbon foam fosters bone growth

The Center of Innovation for Biomaterials in Orthopedic Research (CIBOR) at the National Institute for Aviation Research (Wichita, KS, US) has two patents on the use of carbon foam as a bone-graft material to improve success in orthopedic implants.

Read MoreWheelchair racing glove demands met by CRP USA composites

The strength, durability and light weight characteristics of 3D printed Windform XT 2.0 athletic gear facilitates Paralympics Gold Medalist Tatyana McFadden’s enhanced agility and comfort.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More