Modular, upgradeable, automated composites manufacturing equipment

CAMX 2024: Mikrosam highlights its filament winding automation, AFP and ATL, modular prepreg slitting and rewinding machine, and towpreg production lines for productivity and reduced costs.

Share

Mikrosam (Prilep, Macedonia) is a producer of equipment and automation for several composites manufacturing processes, including: filament winding automation, automated fiber placement (AFP) and automated tape laying (ATL), and in-house modular prepreg slitting systems. With a strong focus on innovation and customization, the company provides customized solutions to meet the needs of its clients, aiming to enhance productivity and reduce production costs.

Mikrosam produces automated lines for composite pressure vessels and high-value products. These lines ensure a lower total cost of ownership, high availability and productivity, with increased throughput and reduced cost per part:

- Multi-spindle high-performance automation

- Patented automatic cut and restart system, exchangeable resin bath

- TCON: Top-level automation and manufacturing historian with SCADA integration.

Mikrosam also introduces a gantry-based multi-axis handling system for composite parts. Gantry handling is crucial in multi-spindle winding, especially for handling tanks and parts exceeding 1,500 L, where robotic handling cannot be used. It is ideal for heavy loads, long travel distances or small workspaces.

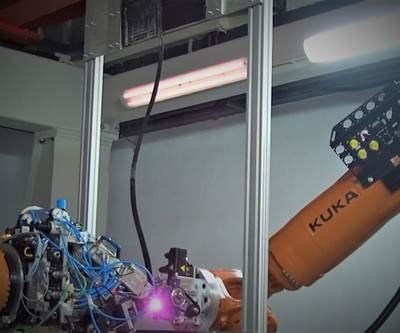

Mikrosam further highlights its AFP and ATL solutions, designed for flexibility, ease of use and scale, which enable users to start with an initial setup that can support business growth. Solutions include multi-material AFP and ATL heads, technology with a head exchange system and the capability for thermoplastics.

Mikrosam offers scalable machines for slitting composite prepregs to different widths and form factors, combined with an inspection system for traceability and detecting errors. The return on investment (ROI) with Mikrosam’s slitting machines is said to be 12 to 18 months. Further improvements and modularity of the system make it well suited for the growing use of slit prepregs.

The company’s customized solution for in-house towpreg production is said to reduce the total production cost, resolve many logistics-related questions and provide higher process and material quality control. The company says that users can expect accurate calibration of towpreg resin content, cost savings and the ability to produce a range of towpreg widths.

Related Content

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Post Cure: Parallel winding technique demonstrates CFRP anisogrid design optimization

Over the years, CIRA has demonstrated its patented CFRP parallel winding technique in a variety of ways for space applications. The lattice structure for the Vega-C launcher stage is a prime example.

-

Optimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Related Content

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MorePost Cure: Parallel winding technique demonstrates CFRP anisogrid design optimization

Over the years, CIRA has demonstrated its patented CFRP parallel winding technique in a variety of ways for space applications. The lattice structure for the Vega-C launcher stage is a prime example.

Read MoreOptimizing robotic winding of composite tanks and pipes

Pioneer in mandrel-based reinforced rubber and composite products, TANIQ offers TaniqWindPro software and robotic winding expertise for composite pressure vessels and more.

Read MoreFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read MoreRead Next

Filament winders specialized for composites hydrogen vessel production

JEC World 2024: A pressure vessel for HydroExceed manufactured via a recently delivered multi-spindle filament winder displays Mikrosam’s expertise in filament winding equipment.

Read MoreMikrosam automates thermoplastic composites with toolless multi-robot placement system

Mikrosam (Prilep, Macedonia) introduces an automated process for fabrication of thermoplastic composites without the use of molds or tools.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read More