New brand identity launch aligns with nonwoven portfolio offerings

CAMX 2024: James Cropper, formerly known as Technical Fibre Products, is bringing its new name to the U.S. composites industry, highlighting its specialization in carrier, surface and fire protection veils, among other products.

Share

James Cropper (formerly Technical Fibre Products Inc.) is highlighting its new brand identify launch. Formally announced in July, it aligns the advanced materials manufacturer with it’s parent company, James Cropper, drawing on a long history of material and technology innovation, while also unveiling a refreshed new image to reflect the company’s forward-thinking ethos.

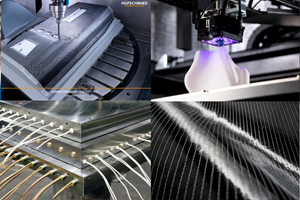

On display at the James Cropper booth is the company’s extensive portfolio of nonwovens that, along with their quality and design flexibility, have always been synonymous with the company. These materials offer a comprehensive range of solutions for composite applications in markets such as aerospace, automotive, advanced air mobility (AAM), wind energy, sporting goods and hydrogen fuel cells. Some typical applications include:

- Carriers: James Cropper’s carrier veils are used extensively in the aerospace industry to provide an effective support for adhesive films and fragile materials. They aid manufacture by ensuring uniform adhesive wet-out and consistent, controlled film thickness, as well as enhancing the resilience and handling of the final product.

- Surface finish: A wide range of lightweight surfacing veils are available which are said to deliver a high-quality, resin rich surface finish to a composite with functionality such as corrosion resistance, wear resistance and static dissipation. They are easy to handle and incorporate, reducing the need for further processing of the finished part.

- Conductives and EMI shielding: A flexible solution for imparting tunable EMI shielding to composites. Easy to handle and seamless to integrate, James Cropper nonwovens provide consistent conductivity and shielding with minimal weight addition.

- Fire protection: The Tecnofire range provides integral and effective fire protection for composites, resisting burn through, flame spread and heat insulation without compromising structure or requiring time-consuming application.

Andy Walton, managing director of James Cropper Advanced Materials, will be attending the show. “CAMX has been an important date in our events calendar for 10 years now and provides an opportunity to launch our new brand identity to the U.S. composite market,” says Walton. “The show always delivers valuable insights into the industry, as well as bringing together all the key composites manufacturers and suppliers.”

Related Content

-

High-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

-

Graphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

-

Highly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Related Content

High-strength, nondestructive adhesive-bonded fasteners

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

Read MoreGraphene-enhanced SMC boosts molded component properties

CAMX 2023: Commercially sold GrapheneBlack SMC from NanoXplore increases part strength, stiffness and provides other benefits for transportation, renewable energy, energy storage and industrial markets.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreCAMX 2023 exhibit preview compilation, Part 2

Part 2 continues to showcase the materials, services, machinery, live demonstrations and other innovations presented by CAMX 2023 exhibitors.

Read MoreRead Next

Technical Fibre Products opens new nonwovens manufacturing line

New line increases nonwoven capacity and extends TFP’s warehousing to support the increase in product and raw materials.

Read MoreTFP glass veils prove integral for fiber-metal laminate applications

A recent study conducted on vacuum-infused thermoplastic fiber-metal laminates has highlighted the performance benefits behind using TFP’s nonwovens for consistent, uniform bondlines and interfacial bonding.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read More