Portable digital ultrasonic imaging achieves in-service, field and manufacturing inspection

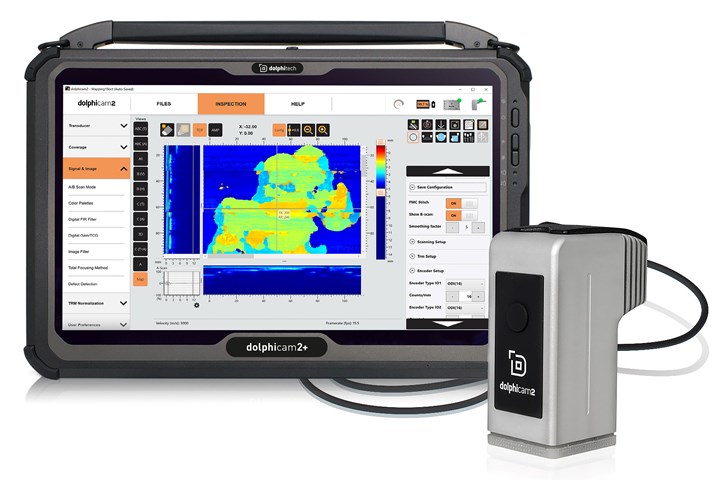

CAMX 2023: 2D array ultrasonic NDT for composites, metals and other materials is made possible through Dolpitech’s dolphicam and dolphicam2+ matrix transducer technology.

Dolphitech (Gjøvik, Norway) delivers 2D array ultrasound nondestructive testing (NDT) technology, widely used for in-service inspection, field inspection and manufacturing. The company’s main products, dolphicam and dolphicam2+, which will be demonstrated at its booth, are used for ultrasound flaw detection — both pulse-echo and through transmission (MxTTU) — for many industry applications and for all materials.

The company offers a wide range of transducer modules (TRM), with up to 16384 (128 × 128) transducer elements and frequencies from 0.7 to 10MHz, making this matrix transducer technology powerful, easy to use and interpret and capable of providing comprehensive data. Dolphicam and dolphicam2+ are especially suited for composite materials like carbon fiber and glass fiber-reinforced (CFRP/GFRP), detecting and inspection impact damage, delamination/debonding, porosity measurements and more. These solutions are also suitable for metallic applications, detecting corrosion, crack detection and adhesive bonding.

Dolphitech offers a range of accessories to go with dolphicam2/dolphicam2+, like water irrigated pipe shoes, replaceable delay-lines and a large area scanning solution (Rapid Mapper).

In particular, the dolphicam2 platform can inspect and detect damage, degradation and defects in mission-critical assets with a setup time of less than 60s. The user-friendly system also means that technicians of all experience levels can generate analysis-ready images of materials in real time for quick decision making, the company says, and the equipment is highly portable.

Dolphicam2’s software is under constant development, delivering functionality needed by customers. Some newer releases include multiple C-scans, defect detection tool, saving and post-processing large area full-matrix-capture (FMC) and multiple language support.

Related Content

-

ORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.

-

Carbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.

-

University of Bristol launches composite materials to space for ISS testing

Next-gen carbon fiber materials will be tested under extreme conditions for 12-18 months to determine their viability in space for use in future space bases, interplanetary travel.