Pultrusion, pull-winding showcase high-volume composites production

JEC World 2024: Exel Composites offers attendees a chance to engage with company experts and learn more about continuous composite manufacturing processes across various industries.

Exel Composites (Vantaa, Finland) invites all industry professionals and enthusiasts to visit its booth to explore advancements in pultrusion and pull-winding technologies. Exel specializes in volume manufacturing of composite profiles and tubes for diverse industrial sectors including wind energy, buildings, transportation, defense and telecommunications, among others.

Exel’s team of composite experts will be available for in-depth discussions and insights into the applications of its continuous composite manufacturing processes across various industries. “We welcome everyone at JEC World to engage with our experts and explore our range of product samples,” Paul Sohlberg, president and CEO at Exel Composites, says.

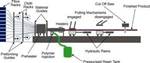

Exel uses continuous manufacturing technologies called pultrusion and pull-winding, which are suited for high-volume, consistent and high-quality production. These are used to manufacture lightweight, robust and long-lasting composite profiles and tubes that are engineered for customers’ specific applications. Exel has decades of experience in developing solutions using different fiber and resins systems. Pultruded and pull-wound composite solutions can be manufactured from various fibers including carbon fiber, glass fiber, natural fibers and others. Some of the most typical resins used alongside carbon fiber and fiberglass reinforcements are polyester, vinyl ester, polyurethane and epoxy.

To meet Exel’s team of pultrusion and pull-winding experts, register for a free ticket to the show by visiting this link.

Visit Exel Composites at Booth 6D97.

Related Content

-

Fiber composite technologies target construction, industrial 3D printing markets

JEC World 2025: KraussMaffei presents innovations for lightweight composite construction and surface technologies, from HP-RTM, LFI and ColorForm to the printCore extruder.

-

Exel Composites supplies fiberglass profiles for Foton electric buses

Partnership with Chinese automotive manufacturer will see the implementation of pultruded profiles in various bus models, backed by weight savings, complex geometries and long life.

-

Cannon introduces in-line resin degassing unit for infusion, RTM and pultrusion processes

Fully automatic system for processing large composite structural parts reduces overall degassing time in a single compact unit.