SmartValves offer improvements over traditional vacuum bag ports

Developed to resolve tilting and close-off issues, SmartValves eliminate cutting through vacuum bags while offering reduced process time and maintenance.

SmartValves are shown at far left and far right, with traditional two-piece vacuum ports in between. Photo Credit: SmartValves, Bert Groenewoud, Earth and Flight Composites.

SmartValves were developed by Bert Groenewoud, a composites technician, instructor and process development engineer with more than four decades of experience in composites fabrication and repair. The valves he developed were in response to issues he experienced during complex vacuum bagging for aircraft structures.

Groenewoud’s experience with composites fabrication and repair is significant. He served as a sheet metal and composites specialist at KLM for 16 years, an advanced composites and metal-bond repair instructor for 13 years and senior process development engineer at Airborne Composites for almost 6 years. A member of the Commercial Aircraft Composite Repair Committee (CACRC) since 1991, Groenewoud is now owner and operator of Earth & Flight Composites a composite repair training company near Amsterdam in the Netherlands which has two composite repair training facility locations in Germany at HEICO Aircraft Maintenance in Leipzig and 4Uexperts in Frankfurt.

“I started working on SmartValves after my years at KLM, while serving as a materials and process engineer at Airborne,” says Groenewoud. “I had long been frustrated by issues with tilting of standard vacuum ports. For example, such ports connect to long and heavy vacuum hoses, which then pressed into the vacuum base plate hole and closed off the valve.”

Standard vacuum ports use a base plate underneath the vacuum bag. In order to attach the top assembly — which has a connection fitting for vacuum hoses — a hole is cut into the vacuum bag at the center of the base plate and the top assembly is twisted to tighten.

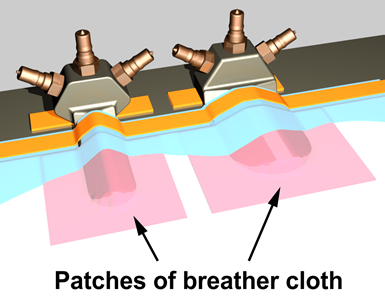

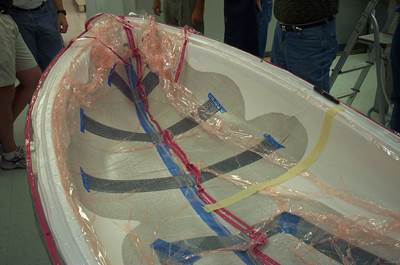

SmartValves are installed at the edge of a vacuum bag (blue), using breather cloth and sealant tape (yellow). Photo Credit: SmartValves, Bert Groenewoud, Earth and Flight Composites.

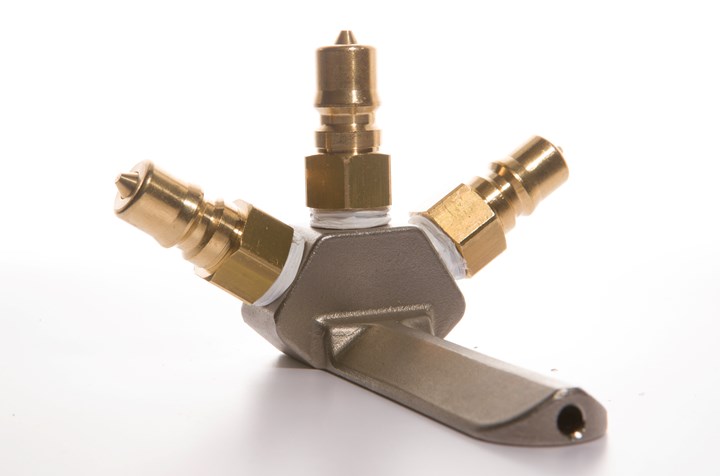

“The SmartValves design eliminates tilting issues by using a flat stainless steel base with channels inside that lead directly to the connect/disconnect fittings,” says Groenewoud. “This design also eliminates pressure points. To install, simply place the valve plate at the edge of the flat or curved area, then cover with a breather ply and the vacuum bag film with sealant tape. Press down to seal the valve plate on both sides and across the top. SmartValves don’t tilt, whereas standard valves must have vacuum applied to avoid this. Even with a vacuum gauge and heavy hoses connected, the Smart Valve stays upright. Plus, you don’t cut the bag and, if you use precut bagging film, you can eliminate the risk of having razors or scissors in the bagging area.”

Groenewoud claims SmartValves provide cost savings by reducing the time to complete vacuum bagging, as well as a longer service life and reduced maintenance due to the one-piece, stainless steel design — the main body of the valve is covered by a lifetime guarantee. SmartValves also resist high temperatures (up to 1,200°F/649°C) and can be applied to flat and curved surfaces and used with all standard vacuum couplings and gauges.

SmartValves are distributed by GMI Aero (Paris, France) and come with a certificate of fabrication. Questions can also be directed to Bert Groenewoud at Earth and Flight Composites.

Related Content

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

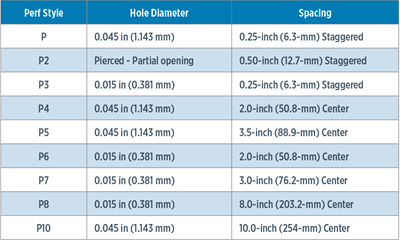

Tech Table: Vacuum bagging supplies

This is the fifth in a series of Tech Tables and comprises vacuum bagging material data provided by suppliers.

Read MoreUnderstanding vacuum bagging layers in production, repair

Recognizing the functions of each layer in a vacuum bag schedule can help users discover what vacuum bag schedules work best for their application.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read More