TPRC publication studies the effects of grit-blasting on titanium-thermoplastic composite joints

Researcher Vanessa Marinosci studies the correlation between mechanical performance and titanium surface morphology of co-consolidated Ti6Al4V-C/PEKK joints.

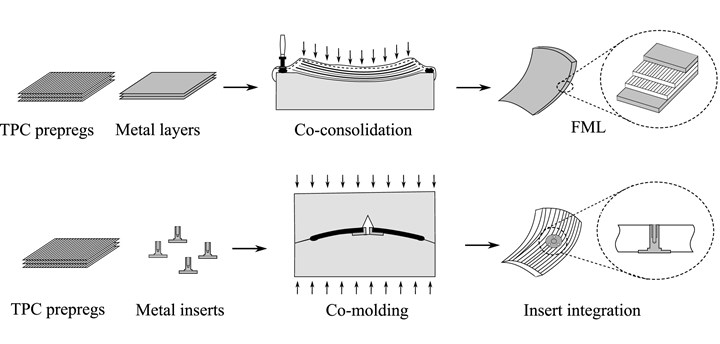

Schematic representation of the co-consolidation process. Photo Credit: Vanessa M. Marinosci, Wouter J.B. Grouve, Matthjn B. de Rooij, Sebastiaan Whijskamp and Remko Akkerman.

ThermoPlastic composites Research Center (TPRC, Enschede, Netherlands) researcher Vanessa Marinosci has recently published an article called “Effect of grit-blasting on the fracture toughness of hybrid titanium-thermoplastic composite joints” in the International Journal of Adhesion and Adhesives. In the article, the correlation between mechanical performance and titanium surface morphology of co-consolidated Ti6Al4V-C/PEKK joints is described.

Various surface morphologies were obtained by grit-blasting the titanium surface using different blasting pressures. Subsequently, test coupons were manufactured by co-consolidating titanium-unidirectional C/PEKK in an autoclave. Topographical characterization of the titanium surface and evaluation of interfacial fracture toughness were carried out, in order to correlate joint mechanical performance to titanium's roughness parameters. Furthermore, crack surface analysis was conducted, by means of optical microscopy, to identify and quantify the failure mechanisms driving joint mechanical performance.

The research was conducted by TPRC in collaboration with the University of Twente (UT, Enschede, Netherlands). The financial support of the Dutch Research Council (NWO) and the TPRC members is gratefully acknowledged.

For more information on this topic, register for the next episode of the TPRC Talks “Joining with Thermoplastic Composites: Facing the Interface” on June 28, 2021 at 4:00 p.m. CET (10:00 a.m. EST).

Related Content

-

Markforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

-

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

-

Queen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.