Uavos delivers curing oven to aerocomposites manufacturer

Composite curing oven meets customer needs with ability to cure complex synthetic and composite parts.

Uavos (Mountain View, Calif., U.S.) has delivered a high-performance Oven-500 composite curing oven to a manufacturer in the aircraft industry. To meet the customer’s needs, this oven was designed to cure synthetic and composite materials of complex contours, shapes and sizes while providing fast heat-up rates and cycle times. Uavos says that its technology helped the business generate lightweight composites with extreme strength that meet the most demanding applications.

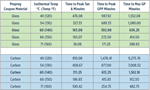

The curing process for composite materials includes bagging and putting them under a vacuum while being cured. The electrically heated Oven-500 is rated for a maximum temperature of 220°C. Workspace dimensions of this oven measure 466 millimeters wide × 2050 millimeters deep × 502 millimeters high.

Top-loading designs incorporate a fully open upper aperture for product entry. Uavos’ Oven-500 comes with side-mounted electric heaters. Highly efficient circulation fans deliver dual airflow, distributing air evenly throughout the entire working space.

A temperature controller and redundant high-limit controller provide precise temperature control and over-temperature protection. This control system has a multitude of capabilities, such as serial communication port, ramp/soak programming, as well as data collection. All the data can be downloaded via a protocol Modbus.

“Our customers are seeking technologies that improve the quality of their products and increase efficiency,” explains Aliaksei Stratsilatau, CEO of Uavos. “Uavos is committed to offering advanced solutions to composite parts manufacturers and developing high-performance curing ovens to meet their specific composite process requirements.”

Uavos is a developer and manufacturer of security and commercial solutions based on advanced unmanned systems with an international investor base. The company’s technology, products and tailored services include multi-role unmanned aerial vehicles (UAVs), proprietary autopilots, advanced communication systems, UAV components and experiential training.

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.