Universal Hydrogen uses dry braided carbon preform tanks as part of plan to decarbonize aviation

Twin-tank module offers low capex option for regional carriers to convert to clean fuel.

Paul Eremenko, former chief technology officer for Airbus SE (Leiden, Netherlands) and United Technologies Corp. (Farmington, Conn., U.S.), has co-founded Universal Hydrogen (Los Angeles, Calif., U.S.) to provide the infrastructure necessary for hydrogen-powered aviation. Air travel accounts for roughly 2.5% of global greenhouse gas emissions. Airbus and the French government have announced plans to address this by developing the first decarbonized commercial aircraft to enter service by 2035. Airbus has announced three preliminary aircraft designs, all based on hydrogen-fueled propulsion.

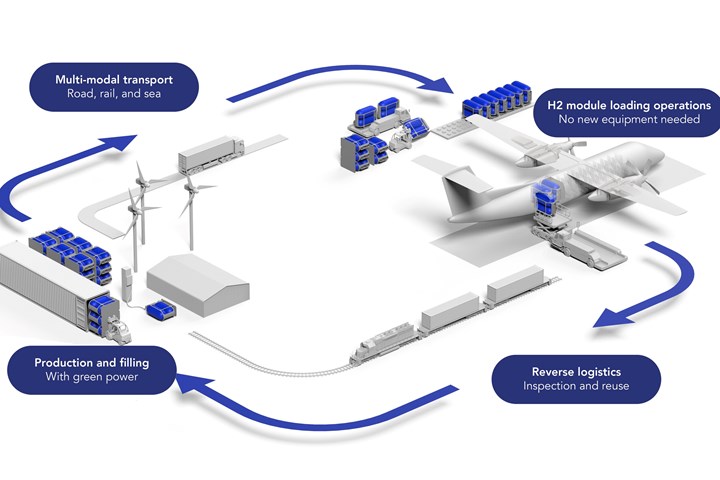

“The key challenge, in our view, is the infrastructure,” says Universal Hydrogen CTO, J.P. Clarke. “Instead of the time and cost to build pipelines and specialized hydrogen transportation systems, we want to leverage the existing containerized freight transportation infrastructure combined with new, efficient technology to provide a low capital investment solution. Our twin-capsule modules enable easy filling, transport and loading onto the aircraft and much lighter weight than batteries. This approach is also scalable. As demand grows, so does the supply network, simply increasing the number of modules in circulation, but with a low barrier to entry.”

Turboprop aircraft conversion

The company plans to kick-start the market by converting ATR and Dash 8 twin-turboprop regional aircraft to hydrogen fuel-cell propulsion. The twin-capsule module developed for these aircraft uses 850-bar cylinders made with a mutli-layered, weight optimized, continuous carbon braided preform over a low permeability membrane for high-pressure storage of hydrogen gas; or two metal tanks, insulated but not actively cooled, to transport liquid hydrogen. The modules have been sized to provide 400 nautical miles of range with high-pressure gas and 550 nautical miles with liquid hydrogen.

Up to three modules will be loaded into the rear fuselage of the planes via the service door, widened slightly as part of the supplemental type certificate (STC) modification. The hydrogen will be plumbed external to the fuselage into the nacelles, each replacing the turboprop engine with a 2-megawatt fuel-cell stack powering an electric motor for the propeller plus a smaller motor for auxiliary power. The fuel-cells use the hydrogen as fuel and emit only water vapor, which is collected and dumped at flight conditions when no contrails are produced for minimal environmental impact. A thermal-management system including a radiator on the nacelle will cool the fuel-cell and motor.

The retrofit has been designed to maintain aircraft performance with the above-stated range based on gas or liquid fuel but does require losing two rows of seats to accommodate the twin-tank modules. The rear galley also moves to the front, losing an additional two seats, for a total capacity reduction of 40 passengers. Despite this, Universal Hydrogen estimates operating economics to be roughly unchanged in terms of cost per available seat mile.

Even though hydrogen is currently more expensive than jet fuel, its cost is expected to come down as the significant production increases announced and planned come online. Eremenko also estimates at least a 25% improvement in maintenance and overhaul costs for a fuel-cell-electric powertrain versus a combustion engine.

Business model, timeframe and partners

Universal Hydrogen plans to offer hydrogen fuel modules and a retrofit kit for converting Dash 8 and ATR aircraft, aiming for a 2024 entry into service. Eremenko has described subsidizing the conversion to hydrogen for regional carriers, essentially offering “a low-to-no-cost conversion” in exchange for a long-term hydrogen fuel contract.

After this initial stage, the company aims to release its conversion plans as an open-source design that can be customized by developers of smaller aircraft, from urban air mobility to the commuter aircraft market. The company plans to partner with OEMs of regional and larger transport airframes, from ATR and De Havilland Canada, to Boeing and Airbus, with a view to de-risking the decision to go with hydrogen.

Universal Hydrogen is advancing toward a finalized design and expects to have a demonstration of the powertrain and fuel modules ready by 2021. Experimental flight testing will follow and then certification. In parallel, the company will mature its hydrogen logistics network and develop a production system for the fuel modules. So far, it has been self-funded by its founders and partners to the tune of around $5 million. It estimates about $300 million will be needed to reach first revenues.

Although Universal Hydrogen will focus on powering aircraft via hydrogen fuel cells, the same fuel modules could also be used to power planes that burn hydrogen in modified jet engines. The company’s target of medium-range, single-aisle aircraft comprise the vast majority of flights globally and offer a huge market potential, says former Airbus CEO Tom Enders, who is advising the startup.

Related Content

3D-printed CFRP tools for serial production of composite landing flaps

GKN Aerospace Munich and CEAD develop printed tooling with short and continuous fiber that reduces cost and increases sustainability for composites production.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreHybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Read MoreRead Next

VIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read More