Composites Use in Consumer Products

The complexity and costs of design and manufacture with composite materials lend them well to structural applications like aircraft wings, boat hulls, and car bodies. However, one of the largest markets by volume for composites is consumer goods, including electronics, sporting goods, bathtubs and swimming pools, bicycles, recreational vehicles (RV) and more.

Latest Consumer Articles

VIEW ALLBcomp, Siux bring natural fiber composites to padel tennis

Flax fibers enter the court through Siux’s GEA padel racquets, delivering high-performance, well-balance sports equipment to a rapidly growing sports market.

Read MoreCarbitex, Blumaka composite insole tackles sport injury prevention

The Carbon Elite Insole combines Carbitex’s ability to provide dynamic flexibility and rigidity where needed with Blumaka’s nonslip insole to prevent initial injury and recurrence for athletes at all levels.

Read MoreComposite innovations feature automotive, water sports, UAV and consumer project versatility

JEC World 2025: Precision, performance and reliability are at the core of Cobra International’s display, involving a front end, portfolio of water sports applications, a fixed wing drone and more.

Read MoreR.F. Innova Srl supports luxury creations through composite waste rework

Founder Enrico Raimondo has developed a technique that enables the reuse of waste accumulated during composites processing.

Read MoreInjection molding expertise achieves composites mobility innovation

JEC World 2025: A partner in three JEC Award products, Engel demonstrates how its injection molding equipment can set new benchmarks in applications like bike handlebars and interior vehicle components.

Read MoreComposites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

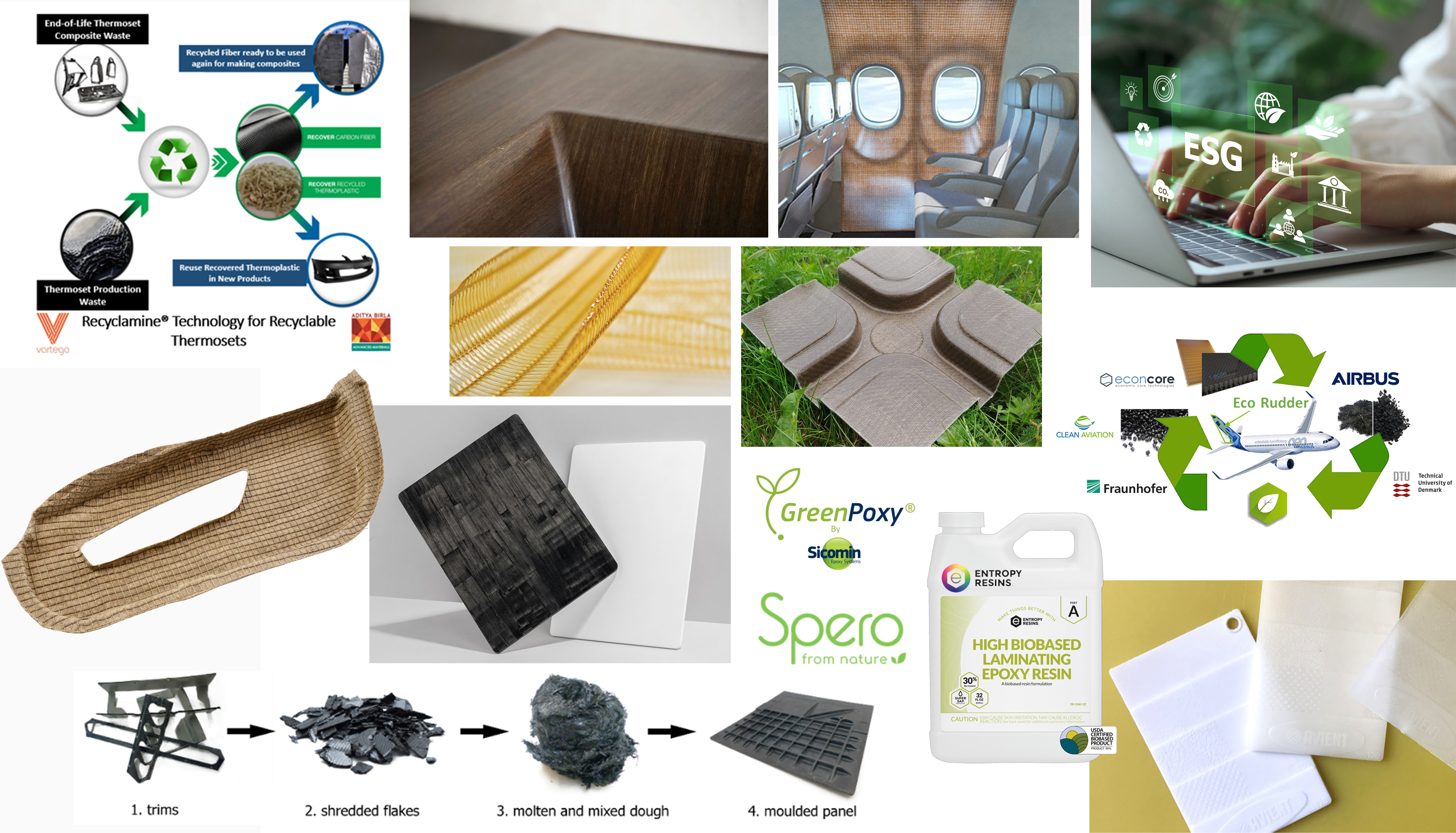

Read MoreKnowledge Centers

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

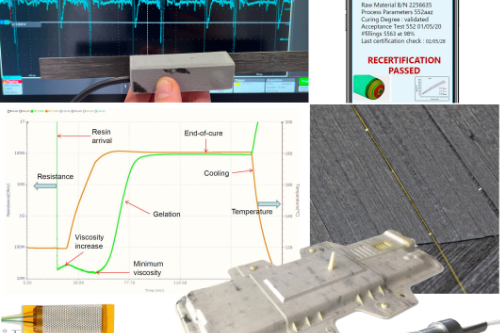

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Consumer News And Updates

Shapers Australia presents Kinetix epoxy systems

The ATL Composites distributor cites the high-performance resin range’s ability to bridge the gap between other polyester and modern epoxy systems, making it well suited to composite surfboard production.

Read MoreExoTechnologies completes testing on recyclable motorcycle helmet

Helmet fabricated from Danu composites demonstrates improved weight reduction, impact resistance and complete recyclability compared to carbon fiber alternatives.

WatchArris debuts consumer-driven brand for carbon fiber tech

Limited-edition products, from footwear to phone cases, will be available through Aurorra by Arris.

WatchDITF, Fiber Engineering highlight biodegradable natural fiber plant pot project

Materials and fabrication process R&D achieves low-cost, compostable plant pots made from invasive hyacinth fibers and a thermoplastic matrix processed via hot press.

Read MoreCarbitex secures capital for next phase of growth in carbon fiber plate footwear

Carbitex Inc. announces the close of a recent funding round, aiding its 2-year effort to restructure the company and expand its global market presence.

Read MoreSelf-balancing electric mobility vehicle developed by Genny Factory SA, RadiciGroup, Acerbis

The two-wheeled personal transporter was redesigned from metal to composite and plastic components to reduce weight while meeting performance standards.

Read MoreFeatured Posts

Repurposing wind blades as functional community art pieces

Ohio-based Canvus Inc. upcycles fiberglass wind blades, car tires and post-consumer plastics to create outdoor furniture that amplifies sustainability messages in community spaces.

WatchPlant tour: Arris Composites, Berkeley, Calif., U.S.

The creator of Additive Molding is leveraging automation and thermoplastics to provide high-volume, high-quality, sustainable composites manufacturing services.

Read MoreRunning shoe insoles get a lift with thermoplastic fiberglass tapes

FlexSpring insoles take advantage of unidirectional, continuous fiberglass and thermoplastics to enable next-level performance for the everyday runner.

Read MoreLighter, stronger, faster bionic hand aided by composites design

Psyonic’s touch-sensing prosthetic hand leverages bionic technology, 3D printing and a carbon fiber composite exterior for light weight, high strength and high-tech functionality.

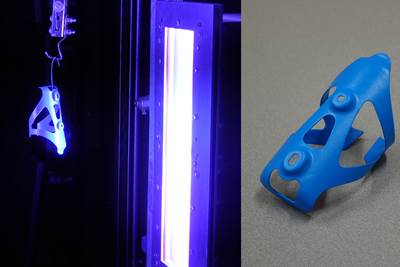

WatchDigital Demo: UV-Cured Powder Coating on Carbon Fiber

Keyland Polymer's R&D chemist will demonstrate the UV powder coating application process followed by UV curing on a carbon fiber water bottle holder. (Sponsored)

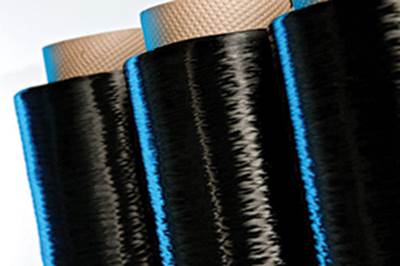

WatchMaterials & Processes: Fibers for composites

The structural properties of composite materials are derived primarily from the fiber reinforcement. Fiber types, their manufacture, their uses and the end-market applications in which they find most use are described.

Read MoreFAQ: Consumer

How are composites used in sporting goods?

Carbon fiber composite bicycle frames are the highest-profile application of composites in sporting goods – but they have also long been used in high-performance fishing rods, tennis rackets, skis, surfboards and more. Protective equipment such as helmets, or high-performance athletic shoes, can also be made with composite materials.

How are composites used in consumer electronics?

Composites are often used under the cover of consumer electronics, such as for components in circuit boards. Composites have also been trialed for lightweight, high-performance laptop and phone covers and other applications.

How are carbon fiber composite bikes manufactured?

Today, many carbon fiber composite bike frames are fabricated and shipped from fabricators in Asian countries, largely incorporating labor-intensive hand layup processes with carbon fiber-reinforced epoxy prepreg. Efforts are being made to develop more bicycle manufacturing in the U.S. and Europe, including more automated processes and thermoplastic materials, or even 3D printing.