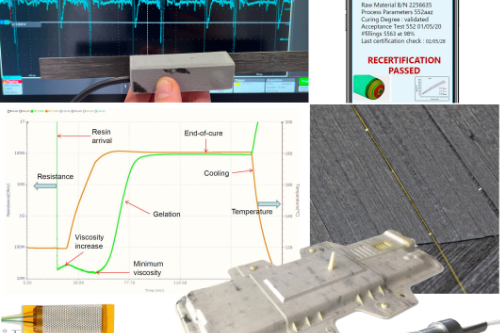

Machining/Drilling of Composites

Machining and drilling processes in composites present unique challenges due to the heterogeneous nature of these materials. Composite structures, often composed of different layers and materials, require specialized techniques to maintain integrity and precision during machining or drilling. Traditional methods used for metals can cause delamination, fiber pullout, or damage to the composite structure. Therefore, specialized tools, such as diamond or carbide-tipped equipment, and specific cutting parameters are employed to ensure clean cuts without compromising the material's integrity.

Latest Machining/Drilling Articles

VIEW ALLHufschmied, CMS open up advanced materials machining potential

Technical partnership combining cutting tool technology and CNC machining will open up new possibilities for comprehensive process efficiency, quality and sustainability for composite materials and engineered plastics.

Read MoreThermwood unveils MAX5 large-scale CNC

Heavy-duty, high-clearance, five-axis CNC router is built to perform in extreme composites machining environments.

Read MoreHG Grimme CNC centers reduce ACE CFRP postprocessing setup

The switch to HG machining centers for the milling of automotive CFRP parts and structural components cuts setup time down from 40-45% to 2-3% and protects against dust generation.

Read MoreRuckus Composites, Aerospace grows in-house composites machining, measurement and inspection

Recent in-house technology investments set Ruckus up to meet advanced composite inspection and precision machining demand.

Read MoreApache Aerospace highlights MX-5 self-feed countersink tool

Third-generation design approved by U.S. aerospace manufacturers targets simplified operations for metal and composite materials cutting.

Read MoreSeven tips for machining composite aerospace components

Machining composite materials is a dusty, arduous and abrasive process that is hard on cutting tools, requiring the right combination of strategies and know-how to properly navigate their dynamics.

WatchKnowledge Centers

Explore the cutting-edge composites industry, as experts delve into the materials, tooling, and manufacturing hurdles of meeting the demands of the promising advanced air mobility (AAM) market. Join us at CW Tech Days to unlock the future of efficient composites fabrication operations.

LEARN MORE

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORELatest Machining/Drilling News And Updates

RoMaNi 2 project enhances industrial robot flexibility for composites, metals machining

Newly developed milling kinematics on a linear axis enables versatile and efficient machining with up to 0.1-millimeter production tolerance.

Read MoreQueen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

Read MoreNorco invests in CNC, kit cutting capability expansion

Transition from internal to external demand over the last few years has evolved Norco’s machining and composite kit cutting equipment, and now includes material outsourcing and digital engineering services.

Read MoreHufschmied Zerspanungssysteme, specialist in composites machining, establishes branch in the U.S.

Supplier of material- and process-optimized cutting tools and technology for CFRP, GFRP and CMC, as well as metals, opened its Chicago facility August 1, 2024.

Read MoreZimmerman highlights five-axis portal milling line

The FZU22 machines various workpiece shapes, sizes and materials including carbon fiber and other fiber reinforcement options.

Read MoreMel Composites adds Rohacryl processing to customized core offerings

Addition of machining services for the Evonik structural foam brand expands Mel’s range of foam core delivery.

Read MoreFeatured Posts

VIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

WatchVIDEO: Precision fabrication of honeycomb materials

MachineTek showcases its precision fabrication of honeycomb materials at CAMX 2024.

WatchDeveloping milling for CMC because grinding takes too long

Economical processes that can cut machining time by 70% are being tested on aeroengine turbine blade demonstrators by Hufschmied and DLR in the SCANCUT project.

Read MoreVIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

WatchCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read More