Composites Use in Military & Defense

One of the main drivers of composites use in defense-related structures – such as components for fighter jets and other aircraft, weapons systems, and to some extent land- and water-based vehicles – is the high temperatures and harsh conditions in which these applications are used. Composite materials also offer high impact resistance, light weight and corrosion resistance needed for work in the field.

Latest Defense Articles

VIEW ALLAngels Aircraft launches pre-seed round to build Archangel UAV

First scalable, flight-ready prototype will incorporate high-rate composites manufacturing, a blended wing airframe and an autonomy-first architecture.

Read MoreVivace delivers fuel tank hardware for Talon-A test vehicles

In its partnership with Stratolaunch to advance U.S. hypersonic capabilities, Vivace has provided both composite and metal tanks for the TA-1 and TA-2 in the past year.

Read MoreAgile Ultrasonics breaks new ground for ultrasonic composites welding in space manufacturing

Continuous ultrasonic welding (CUW) innovation presents the flexibility crucial for future lunar and deep-space missions, but also for composites joining in defense and commercial aerospace.

Read MoreVelocity Composites reinforces key defense partnership with major defense contact renewal

Under a three-year extension, Velocity will continue supplying process material kits for major defense projects for the OEM, reaffirming its broader strategic direction within the sector.

Read MoreHexcel, Specialty Materials launch boron fiber-infused high modulus carbon fiber

High-compression, hybridized unidirectional prepreg targets advanced commercial and military application opportunities.

Read MoreSyensqo composites demonstrate titanium replacement on Boeing MQ-25 Stingray

Validation of integrating Cycom 5250-4HT prepreg into the UAV’s exhaust nozzle structure underpins the material system’s use in other high-temperature aerospace applications.

Read MoreKnowledge Centers

Join us for insights into advanced bonding techniques and welding processes for composite materials to ensure durability and structural integrity.

LEARN MORE

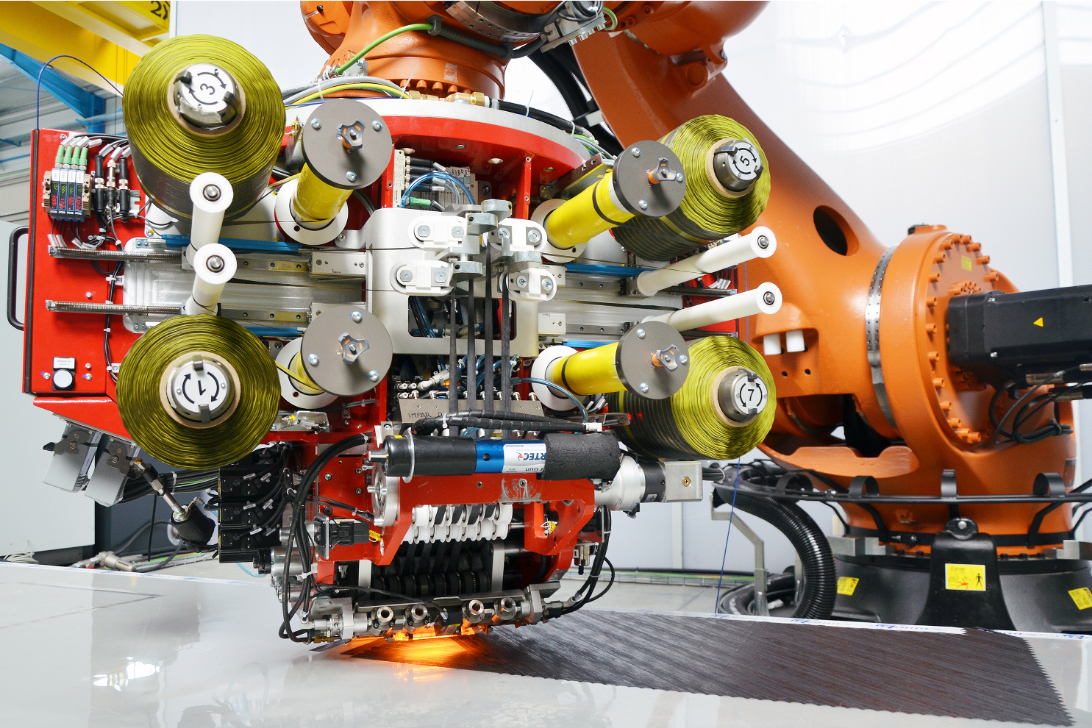

In the Automated Composites knowledge center, CGTech brings you vital information about all things automated composites, from the manufacturing processes to the vendors and necessary tools.

LEARN MORELatest Defense News And Updates

U.S. Navy contract to advance Cambium C/C composites for hypersonics

Cambium aims to further optimize its phthalonitrile-based thermal protection portfolio to create a secure domestic supply for U.S. hypersonics.

Read MoreMaterion metal matrix composites are selected for FLRAA prototypes

Bell Textron is equipping the U.S. Army’s tiltrotor prototype with lightweight materials to further enhance its speed and payload capabilities in operation.

Read MoreCall for abstracts: CW Tech Days to explore high-temperature composite solutions

The fall 2025 installment of CW’s Tech Days online event series will cover high-temperature composite solutions for defense and space applications.

Read MoreBAE Systems honors Polar Technology with Gold Tier award

Quality and delivery of structural composite elements for defense helmet is highlighted in Partner 2 Win program.

Read MoreIntegris to provide composite ballistic protection for Type 45 vessels

Integris Composites enters its fourth decade serving aerospace OEMs and defense contractors globally for critical defense systems.

Read MoreMARS Center milestone powers U.S. hypersonics innovation, workforce development

Utah leaders celebrate the culmination of federal, academic and industry players through MARS, accelerating materials and manufacturing concepts to real-world applications, from thermal protection systems to composites.

Read MoreFeatured Posts

Near-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

Read MoreA return to the Space Symposium: Charting the next frontier

Since 2019 the space sector has been on a rapid upward trajectory. This year’s Space Symposium delivered that same optimism, celebrating the community’s continued proliferation, even as political and financial uncertainty raise new questions.

Read MoreJEC World 2025 highlights: Trends in aerospace, new space and defense

CW editor-in-chief Scott Francis discusses trends in aerospace on display at JEC World — as the composites industry awaits a new single aisle aircraft program, the industry puts continued focus on new space, defense, UAM.

Read MoreThe AAMMC Tech Hub: Ramping U.S. production of large thermoplastic composite aerostructures

CW talks with Syensqo, Spirit AeroSystems and other consortia members about current funding, specification of the next world’s largest press, organizational structure and projects to support U.S. companies in the race to deliver >40,000 sustainable and efficient aircraft over the next 20 years.

Read MoreCarbeon C/C-SiC ceramic matrix composites without fiber coating

Dutch startup Arceon is working with leaders in space, hypersonics and industry to test its Carbeon CMC, validating near-net-shape parts with <3% porosity and performance at 1600ºC, targeting UHTCMC and a presence in the U.S. in 2025.

Read MoreComposites business growth through diversification, innovation

San Diego-based 2024 Top Shops qualifier Rock West Composites gives an overview of its relentless commitment to improvement, including its composite capabilities and its role as a trusted player in the space market.

Read MoreFAQ: Defense

How are composites used in the defense market?

Composites can be used to lightweight defense aircraft and other vehicles, increasing range or allowing higher payloads.

Ultra-high temperature (UHT) composite materials can also be tailored to withstand harsh environments and high temperatures, or to be antiballistic. Research and production of ultra-high temperature (UHT) ceramic matrix composites (CMC), with melting points of 2,500°C (4,532°F) or higher, has ebbed and flowed over the years, following rising and falling demand for applications like hypersonic defense systems and space launch vehicles.

Source: Lockheed Martin expands development, production of ultra-high temp CMCs with facility expansion

Can composite materials be antiballistic?

New materials cntinue to be developed for use as bullet-proof armor for vehicles, infrastructure and equipment.

Historically, antiballistic material designers have preferred tough but expensive aramids, high-density polyethylenes and the like, passing over conventional E-glass as too brittle to have ballistic stopping power.

Proprietary additives and resin systems have enabled the development of bullet-proof fiberglass materials. 3D weaving of carbon fiber, fiberglass or other composite materials can also help to develop high-strength preforms for use as armor materials or molded panels.