PEKK

Eaton developing carbon-reinforced PEKK to replace aluminum in aircraft air ducts

3D printable material will meet ESD, flammability and other requirements to allow for flexible manufacturing of ducts, without tooling needed today.

Peter Zelinski

Former Editor-in-Chief, Additive Manufacturing

Queen’s University Belfast presents research in thermoplastic drilling performance optimization

Researchers have published findings from a multi-objective optimization study on carbon fiber-reinforced PEKK drilling in an effort to better understand the material for use in aviation fastenings.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreMarkforged develops composite 3D printing technology

The FX10, a composite 3D print system with built-in automation, and Vega, a carbon fiber-filled PEKK material from Markforged, expand on 3D printing applications for customers.

Read MorePEEK vs. PEKK vs. PAEK and continuous compression molding

Suppliers of thermoplastics and carbon fiber chime in regarding PEEK vs. PEKK, and now PAEK, as well as in-situ consolidation — the supply chain for thermoplastic tape composites continues to evolve.

Read MoreStratasys collaborates with Lockheed to qualify composite materials for space, aviation end-use parts

Report made public by Metropolitan State University of Denver delivers qualification data for Antero 840CN03 for additively manufactured end-use parts requiring high thermal and chemical resistance, and ESD properties.

Read MoreSolvay completes South Carolina facility installation, adds to U.S. thermoplastic composite capacity

Facility development is fueled by increasing energy, aerospace and automotive demand, and will manufacture UD PVDF, PPS and PEEK tapes.

Read MoreHybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

Stewart Mitchell

Contributing Writer

CAMX 2021 exhibit preview: A&P Technology

A&P Technology’s new product offerings include slit tape thermoplastic fabrics that can be braided into fabrics up to 60 inches wide.

Read More9T Labs assesses AM for medical, aerospace applications

9T Labs conducts two studies to assess the viability of its Red Series additive manufacturing system to manufacture a carbon fiber/PEKK aerospace hinge and a surgical tool.

Read MoreTPRC publication studies the effects of grit-blasting on titanium-thermoplastic composite joints

Researcher Vanessa Marinosci studies the correlation between mechanical performance and titanium surface morphology of co-consolidated Ti6Al4V-C/PEKK joints.

Read MoreOhio State CDME advances AM technology with Cincinnati Inc. MAAM printer

With an additive machine that prints ULTEM, PEEK and PEKK thermoplastics, university researchers and students expect to take 3D printing to new heights, including printing a fully functional turbine and internal combustion engines.

Read MoreHexcel launches electrically conductive PEKK-based carbon fiber material

HexPEKK EM is a high-performance material for additive manufacturing that meets electromagnetic shielding, radiation absorption requirements.

Read MoreHexcel applies additive manufacturing to unmanned aerial vehicle systems

Hexcel’s HexAM process produces stiff, lightweight and complex components that are often too expensive or impossible to produce.

Read MoreWing of Tomorrow ribs: One-shot, thermoplastic, OOA consolidation

GKN Aerospace’s carbon fiber thermoplastic aircraft rib design accomplishes 45-minute cycle times, reduced weight and competitive costs via a customized press system.

Hannah Mason

Technical Editor, CompositesWorld

Swinburne University and CSIRO's Industry 4.0 Testlab for Composite Additive Manufacturing

Australia and Germany collaborate to build Composites 4.0 production line for competitive advantage in next-gen manufacturing and workforce.

Read MoreThe untapped potential in Formula 1 composite manufacture

Formula 1’s midfield teams are struggling to bridge the gap to their better resourced frontrunning counterparts. Could Industry 4.0 composites manufacturing automation level the playing field?

Read MoreRevolutionizing the composites cost paradigm, Part 2: Forming

Boeing-led parts trials explore infusion, compression molding and thermoplastics, offering lessons and supply chain options to better compete with aluminum.

Read MoreRAPM development with PtFS

Boeing-led program explores rapid part cycles using automated, 180-channel thermal control molding cell for infusion, thermoset prepreg and thermoplastic composites.

Read More9T Labs, Arkema present new manufacturing approach for small aerospace parts

The companies demonstrate cost-competitive series production of structural composite parts using carbon fiber/PEKK materials and additive manufacturing.

Read MoreManufacturing the complex geometry parts of RAPM

Boeing-led program explores simulation, tooling, preforming and molding approaches to lower composites part cost.

Read MoreSurface treatment for adhesive bonding: Thermoset vs. thermoplastic composites

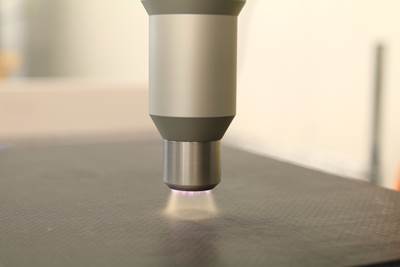

According to BTG Labs, common surface treatment methods like abrasion and plasma treatment work best for different materials.

Hannah Mason

Technical Editor, CompositesWorld

CETMA: composites R&D and innovation in Italy

From design and simulation to inline inspection, induction welding, continuous compression molding and recycled carbon fiber, this lab to support industry is advancing composites in aerospace, automotive, construction and more.

Read MoreRevolutionizing the composites cost paradigm, Part 1: Feedstock

Highly-aligned, short-fiber Tailorable Universal Feedstock for Forming achieves aerospace properties, metal-like formability in zero-waste, fiber-to-parts pilot plant.

Read MoreNew Arkema resins focus on 3D printing, solid-surface applications

The Arkema Group is showcasing its advanced materials solutions developed to meet changing 3D production technologies in the construction, transportation, wind and sporting goods sectors.

Read MoreProving out LMPAEK welding for Multifunctional Fuselage Demonstrator

Clean Sky 2 STUNNING project will manufacture lower thermoplastic fuselage while MECATESTERS will test LMPAEK in conduction and induction welding for parameters, cyclic loading, aging and environmental effects .

Read MoreUsing mobile susceptors to innovate thermoplastic induction welding

IS Groupe and Arkema patent ISW for high-strength UD welds, temperature control and 50% less energy.

Read MoreAdvancing thermoplastic composites and RTM for Clean Sky 2 in Spain

EURECAT leads projects for TPC keel beam, window frames and thermoset RTM fuselage frames with TPC shear ties for next-gen aircraft.

Read More