Composites Processes

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Narrow Your Processes Search

Latest Processes Articles

VIEW ALLComposite curing ovens are built for maximum performance

CAMX 2025: Wisconsin Ovens presents equipment for vacuum bag, filament-wound and honeycomb block heating technologies, offered with a variety of specific features and options.

Read MoreLFAM specialization caters to 3D printed composite tooling, molds

CAMX 2025: AES is committed to driving technological advancement and application development in 3D printing, distinguishing its diverse capabilities through several tooling examples.

Read MoreDamen, CEAD explore composite 3D printing potential via HDPE Workboat project

Dutch innovators collaborate to investigate large-format 3D printing for functional shipbuilding at the recently opened Maritime Application Center.

Read MoreFrom prototypes to performance: Composites company makes inroads to new markets

Top Shops 2024 honoree Calian’s composites division blends R&D, rapid prototyping and scalable production with deep engineering integration and corporate synergy.

Read MoreDelta Marine shares 110-foot custom motor yacht with novel hull

In-progress build highlights Delta’s first hull designed entirely using CFD, a step forward in performance innovation for the shipyard known for its custom composites construction expertise.

Read MoreCEAD launches the Maritime Application Center dedicated to industrial 3D printing boat hulls

The MAC is an LFAM-powered production facility equipped with highly automated, digitally driven manufacturing processes and built around a collaborative model to develop the boats of the future.

Read MoreKnowledge Centers

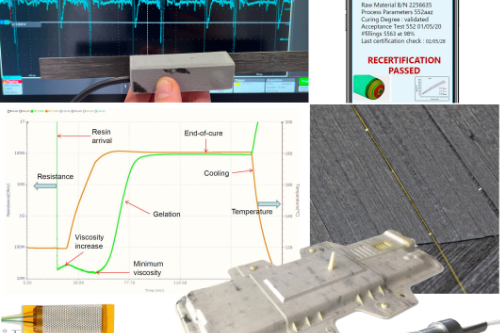

Discover the types of sensors being used in composites, the physics on which they�re based, their installation, promised benefits and challenges, as well as the potential they offer for even further developments in smart structures.

LEARN MORE

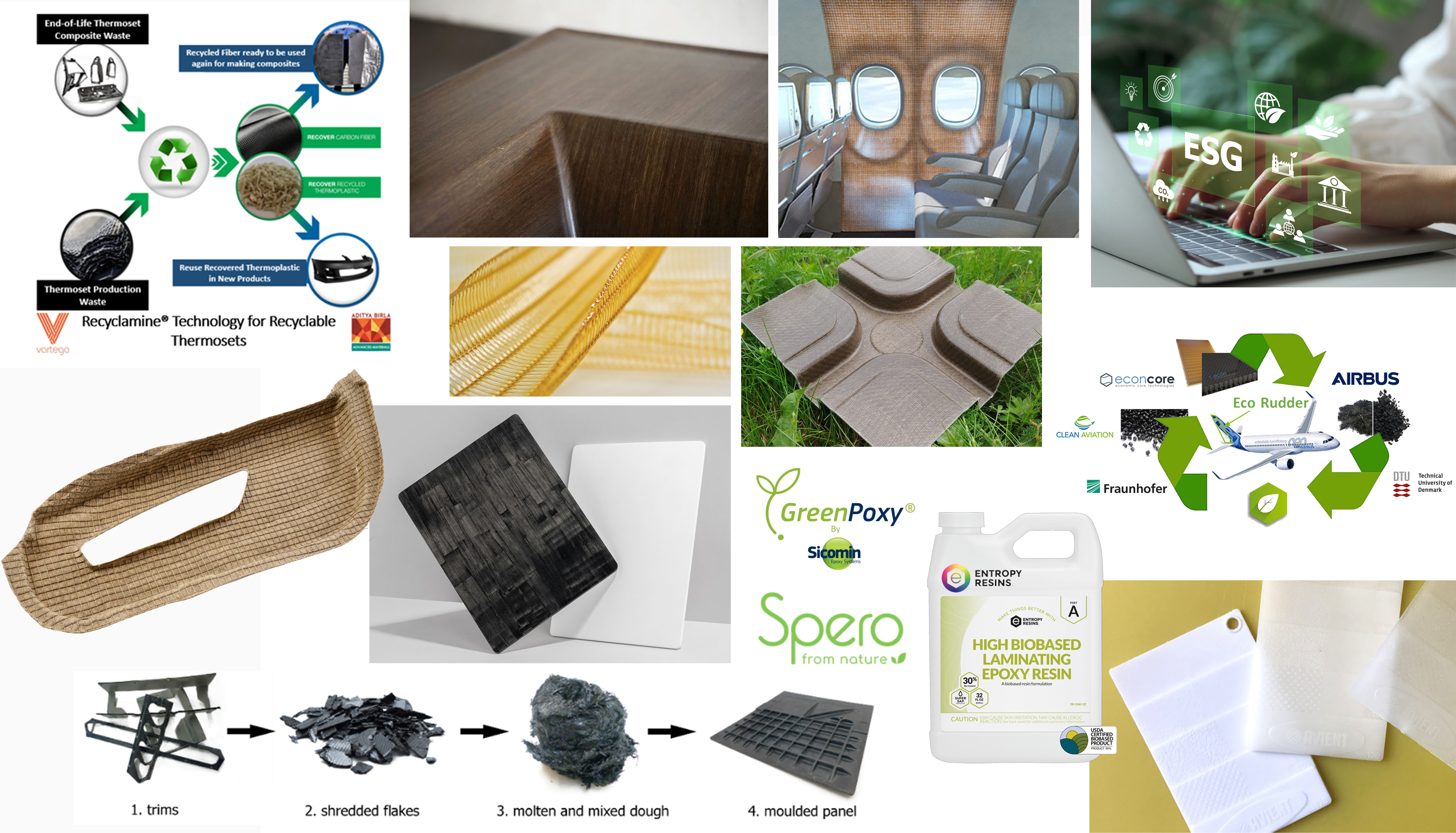

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Processes News And Updates

Swinburne highlights composites and Industry 4.0 activities

Swinburne University of Technology’s facilities and research expertise have attained milestone developments in a UAV wingbox, customized carbon fiber components, digital manufacturing and 3D printing.

Read MoreHufschmied, CMS open up advanced materials machining potential

Technical partnership combining cutting tool technology and CNC machining will open up new possibilities for comprehensive process efficiency, quality and sustainability for composite materials and engineered plastics.

Read MoreCEAD technologies supports FIDAMC advanced manufacturing

CEAD-powered microfactories for composites additive manufacturing builds the Spanish technology center’s collaborative environment, enables expansion into new industries.

Read MoreVacuum-assisted extrusion improves performance of FRP prints

A novel 3D printing approach developed by ORNL reduced internal porosity by up to 75% in large-scale, 3D printed composites.

Read MorePorsche develops TABASKO method for lightweight vehicle series production

Patented carbon fiber-reinforced polypropylene tape-based process supports cost reduction, light weight and thinner walls without sacrificing rigidity.

Read MoreClean Sky 2 outer wing box demonstrator validates OOA LRI, shimless assembly and SHM

Full-scale wing box project achieves TRL 5 with 2% weight reduction and 4% reduction in recurring production costs through improved manufacturing efficiency and assembly processes.

Read MoreFeatured Posts

Spanish startup to ramp up production of “recyclable” EV prototype

Liux’s BIG electric vehicle features multiple structural components manufactured via RTM from flax fabric and a thermoset resin said to enable the entire component to be recycled and reused again.

WatchAddressing rivet hole drilling challenges for aerospace composites

Kennametal explores technological advancements in composite drilling, including stacked laminates, to meet aerospace applications and sustainability challenges.

Read MoreIn oil and gas, an additive manufacturing standard (API 20T) will aid adoption of composites

Polymer AM equipment maker Roboze sees how the oil and gas industry’s way forward with additive is like that of another high-stakes industry, aerospace, and also different in important aspects.

WatchJEC World 2025 highlights: New thermoplastics, PI fiber, solutions for FR, machining, digitized processes and more

CW senior technical editor Ginger Gardiner discusses latest developments in composites from this year’s show.

WatchPlasma moves beyond improved bonding to coatings, multifunctional composites

Plasmatreat cold plasma systems clean, activate surfaces and apply nanocoatings for dielectric barriers and more.

WatchInside the MFFD — CW's coverage of the Clean Aviation multifunctional fuselage demonstrator

CompositesWorld rounds up coverage of the MFFD project over the past decade. Now complete, the MFFD illustrates numerous processes and technologies for manufacturing primary aerospace structures using thermoplastic composites.

Watch