Automation in Composites

AES explores robot vs. gantry for large-format additive manufacturing

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

Peter Zelinski

Former Editor-in-Chief, Additive Manufacturing

Flyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

Read MoreLaser cleaning in composites manufacturing

Laser cleaning technologies for cleaning production molds for composites offer alternatives to harsher, less-friendly methods with features like automation and higher power cleaning.

Read MoreTAVieDA project team cuts aircraft door production time using thermoplastic composites, welding

Fraunhofer groups, Trelleborg and Airbus develop modular, fully automated assembly system concept to replace metals and time-consuming assembly that shows potential for scalability.

Read MoreCartken autonomous robot facilitates indoor, outdoor material handling

Cartken Hauler provides efficiency and flexibility in industrial and on-site material transportation settings through its all-terrain mobility, high payload capacity and rapid deployment.

Read MoreJEC World 2025 highlights: Trends in aerospace, new space and defense

CW editor-in-chief Scott Francis discusses trends in aerospace on display at JEC World — as the composites industry awaits a new single aisle aircraft program, the industry puts continued focus on new space, defense, UAM.

Read MoreZeroAvia is awarded U.S. Air Force grant for autonomous hydrogen-electric aircraft

ZeroAvia will analyze the potential for developing and delivering an autonomous aircraft with hydrogen-electric propulsion for reduced engine noise and low thermal signature.

Read MoreIncreased molding productivity via additive manufacturing

Companies in multiple segments turn to 3D printing for end-of-arm tools, fixtures for increased safety and functionality, lower cost and faster turnaround times.

Peggy Malnati

MMT, Contributing Writer, MoldMaking Technology

UDRI opens RAAM lab to advance robotic femtosecond laser

RoboCLASP, an athermal ablation system initiated for preparing composites for bonded assembly, is being roboticized to advance U.S. Air Force needs.

Read MoreTechnology center demonstrates comprehensive aerocomposite manufacturing initiatives

JEC World 2025: Ideko illustrates its expertise in process and product monitoring equipment, from featuring first results of the HERFUSE project to displaying continuously evolving technologies.

Read MoreSpin-off shares expertise in filament winding software, robotics

JEC World 2025: With two decades of experience, Taniq aims to strengthen its position as a go-to-expert in robotic filament winding, feature its developed winding systems and TaniqWind Pro software.

Read MoreFilament winding, tape wrapping equipment focus on reliability, quality

JEC World 2025: Engineering Technology Corp. (ETC) is exhibiting everything from its filament winders portfolio to a new winder control system, emphasizing range, adapatability and high production quality.

Read MoreEnd-to-end automation system progresses composite material deposition capabilities

JEC World 2025: Loop Technology, a JEC Composites Innovation Award winner, will showcase how its FibreLine system advances the speed and accuracy of composite preforming.

Read MoreVIDEO: Robots enable nine-axis machining of composites

Machine Tool Camp displayed its hybrid machining center at CAMX, featuring nine-axis machining capability enabled by robotics.

Read MoreModular, robotic cells enable high-rate RTM using any material format

Airborne’s automated ply placement systems at Airbus, GKN Aerospace and Teijin Automotive Technologies aim to maximize flexibility and intelligent automation.

Stewart Mitchell

Contributing Writer

McClarin Composites partners with ExxonMobil to accelerate high-speed RTM

Multimillion-dollar investment to drive next-gen automated RTM technology will open new applications and markets for composites OEMs.

Read MoreSAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

Read MoreRoMaNi 2 project enhances industrial robot flexibility for composites, metals machining

Newly developed milling kinematics on a linear axis enables versatile and efficient machining with up to 0.1-millimeter production tolerance.

Read MoreZünd, Loop Technology partner on FibreLine preforming system

Pairing Loop Technology’s automation with Zünd digital cutters provides faster cutting, less stray fibers, higher ply accuracy and more precise preforms for composite aerostructure manufacturing.

Read MoreLoop Technology completes installation of composite preformer with long-reach robots

Delivery of 21-meter track, industrial robot arms and new cutting equipment enable the manufacture of large composite aerostructures at the Loop Technology Centre.

Read MoreMaking an effort to move industry forward

A reflection on the insights, connections and collaboration afforded by attending composite industry events like SPE ACCE and CAMX.

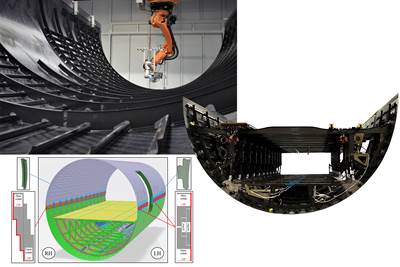

Read MoreManufacturing the MFFD thermoplastic composite fuselage

Demonstrator’s upper, lower shells and assembly prove materials and new processes for lighter, cheaper and more sustainable high-rate future aircraft.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

VIDEO: Painting parts with self-learning robots

LestaUSA’s self-learning robots on display at CAMX 2024 enhance composites manufacturing workflow and workforce needs.

Read MoreACoSaLUS project develops fully automated FPP layup for legacy sandwich parts

Joint R&D project results show 7 times improvement in layup rates, reduced material deployment and development of novel layup features when using FPP for aerospace production.

Read MoreMVP partners with LestaUSA to bring robotics to composites

Self-learning robotic solutions are designed to simplify the automation process for composites manufacturers of all sizes wanting to incorporate automated spray applications.

Read MoreIPD system, robotic spray demonstration enhances composites productivity

CAMX 2024: Magnum Venus Products (MVP) presents several automation solutions, including a self-learning robot, an IPD system and several live demonstrations of its products.

Read MoreAerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreCustom automation equipment meets complex composite challenges

CAMX 2024: Accudyne Systems is highlighting its capabilities to develop, design, build and deliver custom composites equipment.

Read More