Filament Winding

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Latest Filament Winding Articles

VIEW ALLRWC delivers composite frac plugs for downhole environments

Filament-wound fiberglass/epoxy frac plug billets, developed as part of a contract with an oilfield service company, address the very demanding performance needs of oil and gas.

Read MoreExel, Flying Whales advance airship R&D collaboration

This time, Exel has signed a contract to deliver 75 kilometers of pull-wound carbon fiber tubes for the LCA60T VTOL aircraft.

Read MoreHigh-tension, vertical filament winding enables affordable flywheel energy storage system

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.

WatchPost Cure: Parallel winding technique demonstrates CFRP anisogrid design optimization

Over the years, CIRA has demonstrated its patented CFRP parallel winding technique in a variety of ways for space applications. The lattice structure for the Vega-C launcher stage is a prime example.

Read MoreEpsilon Composites to advance H2 composite tank production with Mikrosam filament winder

Modularly designed system enables easy integration into existing production environments, support Epsilon’s ambitious development projects.

Read MorePlant tour: Hexagon Purus, Kassel, Germany

Fully automated, Industry 4.0 line for hydrogen pressure vessels advances efficiency and versatility in small footprint for next-gen, sustainable composites production.

Read MoreKnowledge Centers

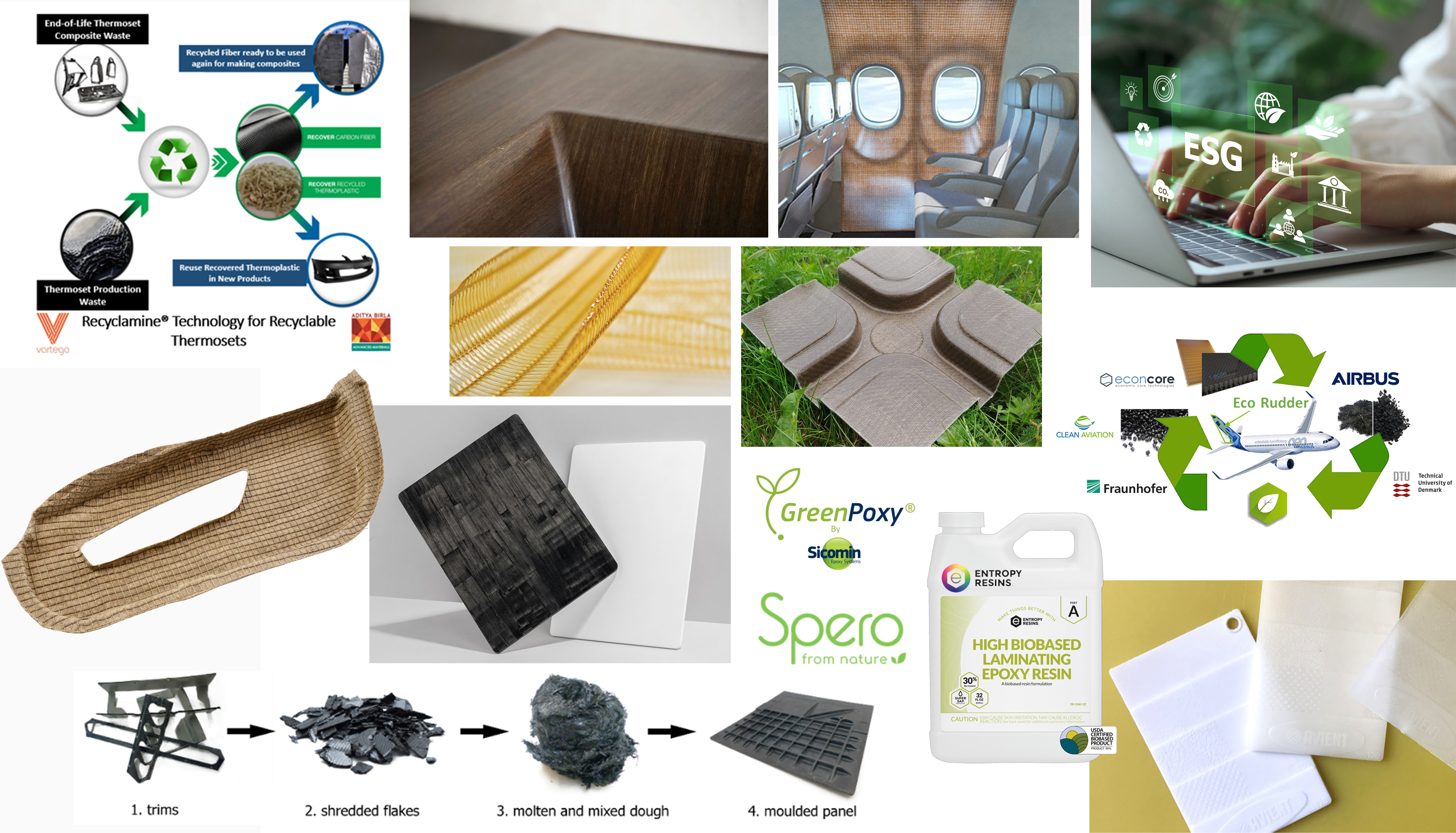

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

CW’s editors are tracking the latest trends and developments in tooling, from the basics to new developments. This collection, presented by Composites One, features four recent CW stories that detail a range of tooling technologies, processes and materials.

LEARN MORE

During CW Tech Days: Thermoplastics for Large Structures, experts explored the materials and processing technologies that are enabling the transition to large-part manufacturing.

LEARN MORELatest Filament Winding News And Updates

Conbility thermoplastics system installation supports TITK R&D

LATW and tape winding machine enhances TITK Rudolstadt’s ability to conduct advanced thermoplastic R&D projects, particularly for aerospace.

Read MoreConbility delivers laser-safe TPC winding cell to FIBRE Bremen

Turnkey winding system will support the German institute’s aerospace R&D efforts, including LATW, tape placement with in situ consolidation and a later thermoset upgrade.

Read MoreComposites specialist celebrates 30 years of CFRP innovation

JEC World 2025: CompoTech PLUS is recognizing three decades serving the composites industry, highlighting latest material and fiber winding technology developments.

Read MoreSpin-off shares expertise in filament winding software, robotics

JEC World 2025: With two decades of experience, Taniq aims to strengthen its position as a go-to-expert in robotic filament winding, feature its developed winding systems and TaniqWind Pro software.

Read MoreFilament winding, tape wrapping equipment focus on reliability, quality

JEC World 2025: Engineering Technology Corp. (ETC) is exhibiting everything from its filament winders portfolio to a new winder control system, emphasizing range, adapatability and high production quality.

Read MoreAnemoi installs 35-meter-tall composite rotor sails on Sohar Max maritime vessel

Carbon fiber-reinforced epoxy composites are key to building these long-lasting wind propulsion technologies for energy-efficient watercraft.

Read MoreFeatured Posts

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreBeyond filament winding: Fabricator expands into sensor technology, hydrogen tanks and more

CW Top Shops 2024 honoree B&T Composites’ story includes diversification into new markets and technologies like photonics-based structural health monitoring, aerospace and hydrogen tanks.

WatchSRI develops scalable, infiltration-free ceramic matrix composites

Work in two DOE projects is demonstrating C/C-SiC produced in 3-5 days with <5% shrinkage, <10% porosity and 50% the cost of conventional C/C and C/C-SiC.

Read MoreOptimized CFRP gantry beam enhances Ultimate cutting machines

CompoTech, Kongsberg PCS collaboration integrates foam-cored design, automated placement of pitch and PAN fibers to achieve award-winning increase in speed and precision.

Read MoreCFRP planing head: 50% less mass, 1.5 times faster rotation

Novel, modular design minimizes weight for high-precision cutting tools with faster production speeds.

Read MoreFilament winding increases access to high-performance composite prostheses

Steptics industrializes production of CFRP prostheses, enabling hundreds of parts/day and 50% lower cost.

Read More