Space

Composites have been used in space since our early steps into the cosmos. Often turned to for their light weight and high strength, these materials have a history of use in spaceflight in such applications as payload fairings, satellite structures and heat shields. ► Explore the technologies, materials and strategies used by composites manufacturers working in the evolving space market at our virtual CW Tech Days: New Space Applications. Learn more and register here!

ESSENTIAL READING

VIEW ALLComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreMaterials & Processes: Composites fibers and resins

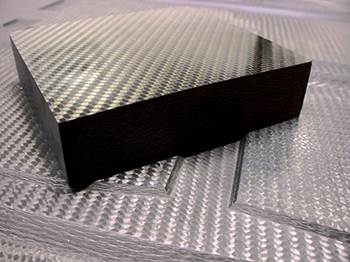

Compared to legacy materials like steel, aluminum, iron and titanium, composites are still coming of age, and only just now are being better understood by design and manufacturing engineers. However, composites’ physical properties — combined with unbeatable light weight — make them undeniably attractive.

Read MoreMaterials & Processes: Resin matrices for composites

The matrix binds the fiber reinforcement, gives the composite component its shape and determines its surface quality. A composite matrix may be a polymer, ceramic, metal or carbon. Here’s a guide to selection.

Read MoreMaterials & Processes: Introduction

High strength at low weight remain the winning combination that propels composite materials into new arenas, but other properties are equally important. This article outlines the case for composites and introduces SourceBook's overview of the materials and processes used to make them.

Read MoreKnowledge Centers

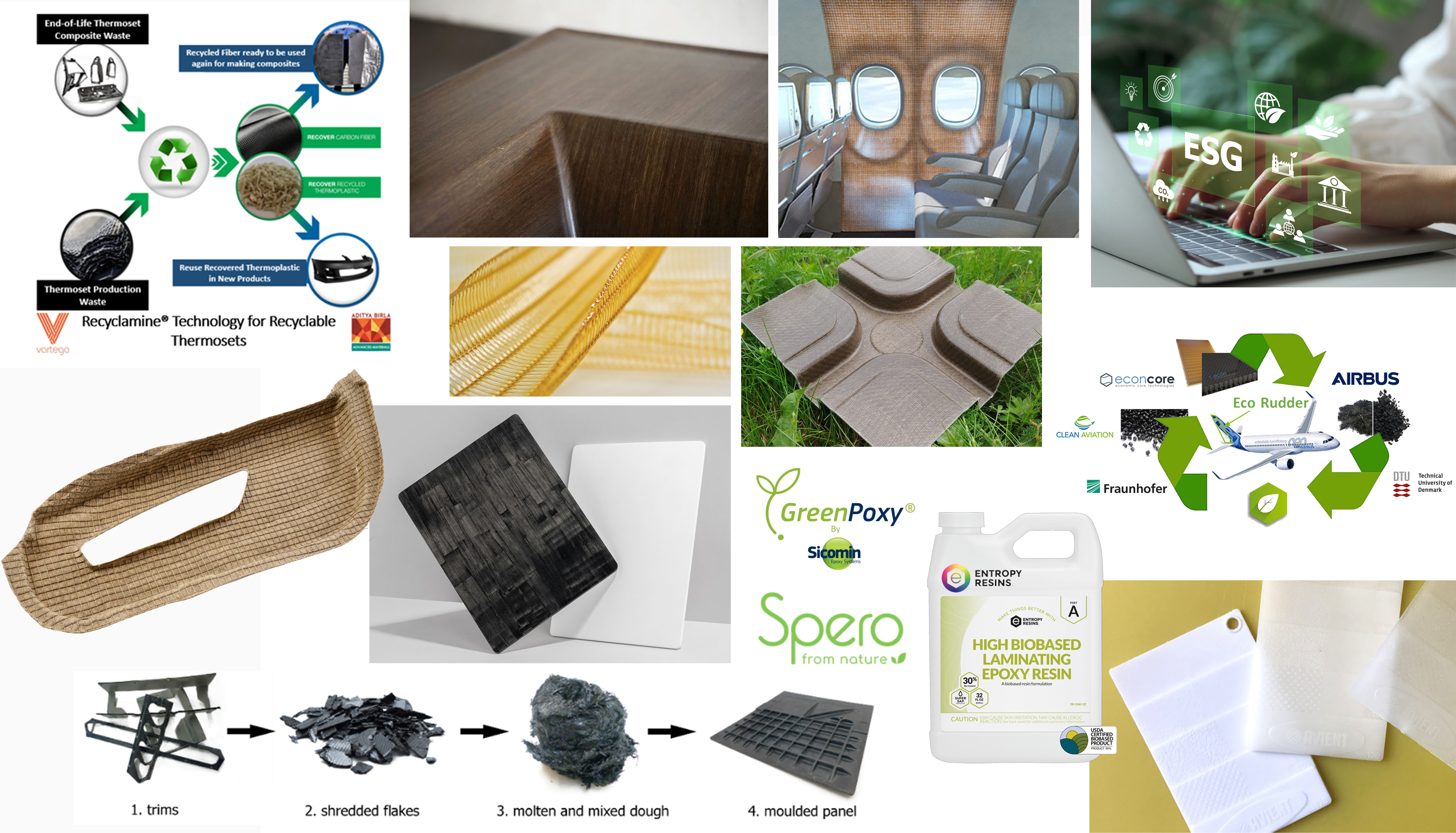

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORE

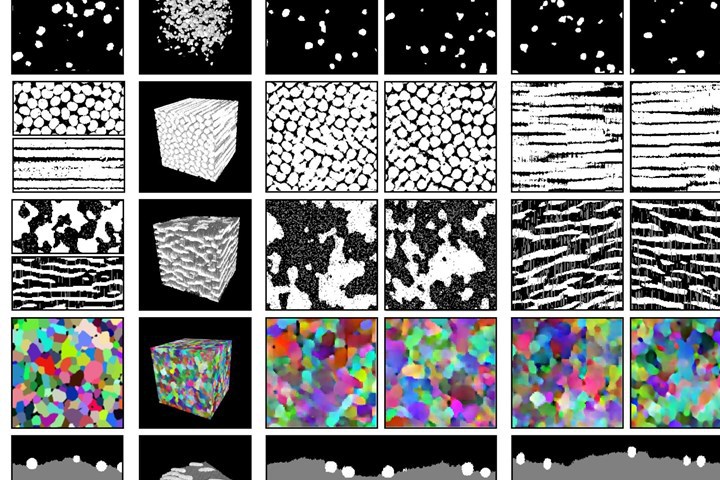

Review the state of the art in design, simulation, failure analysis, digital twins, virtual testing and virtual inspection.

LEARN MORELatest Space News And Updates

Australia’s Gilmour Space prepares Eris 1 rocket for maiden launch

With airspace arrangements finalized and mandatory notice given to the Australian Space Agency, the company is preparing for liftoff no earlier than May 15.

WatchRocket Lab Neutron rocket to support U.S. Space Force NSSL

Space rocket company to join $5.6 billion National Security Space Launch (NSSL) program, an opportunity to on-ramp its carbon fiber composite Neutron vehicle.

Read MoreRocket Lab awarded HASTE launch contract for U.S. DOD

Under the MACH-TB 2.0 program led by Kratos, Rocket Lab will launch its full-scale HASTE rocket, a suborbital version of the Electron, to expand testing of hypersonic technologies.

Read MoreCall for abstracts: CW Tech Days to explore high-temperature composite solutions

The fall 2025 installment of CW’s Tech Days online event series will cover high-temperature composite solutions for defense and space applications.

Read MoreFirefly Aerospace to develop CMC rocket engine nozzle extension

Contracted by the AFRL, Firefly will use its expertise to design, build and test a composite-based nozzle extension to reduce costs, improve performance and accelerate rocket engine production.

Read MoreFirefly awarded DOD contract for responsive on-orbit mission

Mission will use Firefly’s Elytra spacecraft vehicle, supported by proven avionics, composite structures and propulsion systems, to perform on-demand orbital maneuvers and space domain awareness.

Read MoreFeatured Posts

Near-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

Read MorePost Cure: Composite assemblies orchestrate smaller satellite designs, payload flexibility

CubeSats have become key to space exploration and R&T development, though they are often expensive to build and launch. Funded efforts like the DiskSat program aim at mitigating these challenges.

Read MoreA return to the Space Symposium: Charting the next frontier

Since 2019 the space sector has been on a rapid upward trajectory. This year’s Space Symposium delivered that same optimism, celebrating the community’s continued proliferation, even as political and financial uncertainty raise new questions.

Read MorePost Cure: Parallel winding technique demonstrates CFRP anisogrid design optimization

Over the years, CIRA has demonstrated its patented CFRP parallel winding technique in a variety of ways for space applications. The lattice structure for the Vega-C launcher stage is a prime example.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreDesign for manufacturing, assembly and automation enables complex CFRP telescope supports

Airborne delivered two mirror support structures for the FYST and SOLAT telescopes, assembling 26,300 components while maintaining near-zero CTE, strict tolerances on 6.5 × 6.5 × 1.8-meter assemblies.

Watch