Composites Use in Marine Applications

Infused, fiberglass/polyester composite boat hulls have been built since the mid-1900s, expanding over time to include additional resins and foam cores. Composites continue to be a mainstay for various types of boats and luxury and racing yachts, and now include newer innovations such as carbon fiber precision hydrofoils and recycled carbon fiber or bio-based resins.

Latest Marine Articles

VIEW ALLDamen, CEAD explore composite 3D printing potential via HDPE Workboat project

Dutch innovators collaborate to investigate large-format 3D printing for functional shipbuilding at the recently opened Maritime Application Center.

Read MoreDelta Marine shares 110-foot custom motor yacht with novel hull

In-progress build highlights Delta’s first hull designed entirely using CFD, a step forward in performance innovation for the shipyard known for its custom composites construction expertise.

Read MoreCEAD launches the Maritime Application Center dedicated to industrial 3D printing boat hulls

The MAC is an LFAM-powered production facility equipped with highly automated, digitally driven manufacturing processes and built around a collaborative model to develop the boats of the future.

Read MoreUTComp NDT inspection prepares FRP Class 40 racing sailboat

Ahead of the competitive Globe40 competition in September, UTComp’s ultrasonic capabilities were used to test the viability of the craft’s carbon fiber mast, boom and bowsprit on the water.

Read MoreRoyal3D uses large-scale 3D printing for aquatic drone production

ShearWater aquatic drone, manufactured with fiberglass-reinforced recycled PETG, demonstrates precision 3D printing capabilities, sustainability focus and design innovation for maritime and heavy-duty applications.

Read MoreIntegris to provide composite ballistic protection for Type 45 vessels

Integris Composites enters its fourth decade serving aerospace OEMs and defense contractors globally for critical defense systems.

Read MoreKnowledge Centers

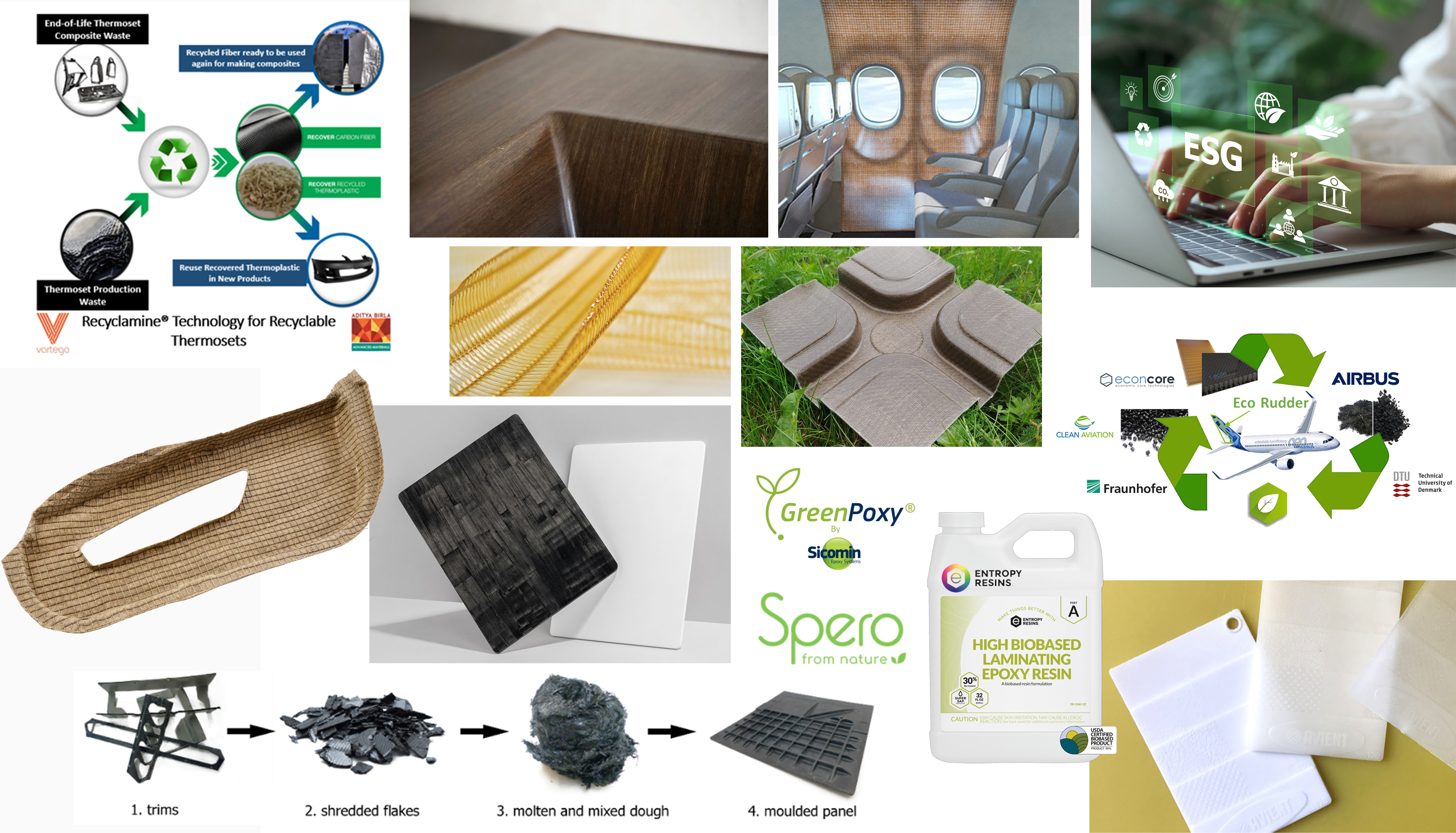

The composites industry is increasingly recognizing the imperative of sustainability in its operations. As demand for lightweight and durable materials rises across various sectors, such as automotive, aerospace, and construction, there is a growing awareness of the environmental impact associated with traditional composite manufacturing processes.

LEARN MORELatest Marine News And Updates

Vabo Composites hatches, doors to be used in Dutch naval project

Multiyear contract with ASWF Damen Naval will contribute lightweight composite products for the development of modern naval vessels.

Read MoreTidalHeath project supports SHM advancements in tidal turbine foils

ÉireComposites, University of Galway and ORPC are dedicated to improving real-time damage detection and monitoring of composite tidal foils through innovations in 3D printed fiber optic sensors and foil designs.

Read MoreProteus Marine Renewables installs Japan’s first 1.1-megawatt tidal turbine

Carbon fiber tidal turbine generator, featuring a horizontal-axis rotor with three composite blades, drives Japan’s transition to tidal energy.

Read MoreClassNK grants approval in principle to OceanWings wingsail

Technical viability of the composite wind-assisted propulsion technology has been verified, aids OceanWing’s expansion into current and new markets.

Read MoreIPS Adhesives debuts Scigrip SG2000 adhesive in North America

The adhesive’s 1:1 mix ratio and long open time provides transportation, construction and marine industries with much-needed routine simplification and flexibility.

Read MoreGurit re-signs long-term supply contract with U.S. Marine Inc.

Multiyear defense contract continuing support for technical composite innovations upholds Gurit’s multi-market strategy.

Read MoreFeatured Posts

FIDAMC expands composites R&D into new markets and advanced manufacturing centers

Pioneering technocenter advances RTM, thermoplastic composites, additive manufacturing, microwire, novel lighter weight LSP and more.

Read MoreFunctionalizing surfaces for sustainability

Riblets reduce drag, fuel consumption, CO2 emissions and noise while boosting power output, flow rates, speed and efficiency.

WatchComposites end markets: Boatbuilding and marine (2025)

As 2023-2024 consumer demand slows, boat and marine vessel manufacturers continue to focus on decarbonization and new technologies using composites.

Read MoreLarge-format AM speeds plug production for manufacture of composite boat molds

Hungarian manufacturer Rapid Prototyping transitioned its conventional foam milling process to 3D printing to produce faster, higher quality, recyclable foam plugs and composite boat molds.

WatchDeveloping bonded composite repair for ships, offshore units

Bureau Veritas and industry partners issue guidelines and pave the way for certification via StrengthBond Offshore project.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreFAQ: Marine

How are composites used in boatbuilding?

Boats and yachts have featured fiberglass composite boat hulls, decks and other structures for many years. These are typically fabricated via infusion, hand layup and/or sprayup methods. Carbon fiber/epoxy can be used in applications requiring even lighter weight to increase speed or fuel efficiency, such as in sailing boats or racing boats.

More recently, new international regulations have allowed developments in composite decks, superstructures, rudders and other components for large ships as well.

Why use composites in boatbuilding and marine applications?

- Composites are attractive in marine applications due to corrosion resistance, as well as lightweighting that composites can provide compared to metals or wood can reduce fuel use, greenhouse gas emissions and vessel draft, helping to improve sustainability.

- Source: Removing barriers to lightweighting ships with composites