SHM

Sensors: Data for next-gen composites manufacturing

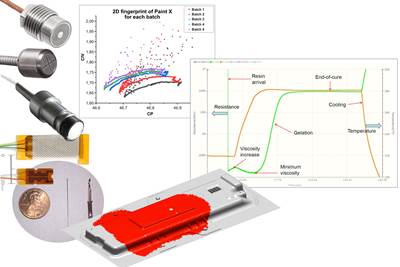

In the quest for sustainability, sensors are reducing cycle times, energy use and waste, automating closed-loop process control and increasing knowledge to open new possibilities for intelligent manufacturing and structures.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Clean Sky 2 outer wing box demonstrator validates OOA LRI, shimless assembly and SHM

Full-scale wing box project achieves TRL 5 with 2% weight reduction and 4% reduction in recurring production costs through improved manufacturing efficiency and assembly processes.

Read MoreTidalHeath project supports SHM advancements in tidal turbine foils

ÉireComposites, University of Galway and ORPC are dedicated to improving real-time damage detection and monitoring of composite tidal foils through innovations in 3D printed fiber optic sensors and foil designs.

Read MoreIMT Nord Europe launches COMPOLIS initiative

COMPOLIS is an R&I hub bringing together industrial partners, dedicated to connected materials and structures with the ultimate goal of digitalizing composite materials.

Read MoreÉireComposites joins TOSCA project tackling aerocomposite hurdles

Epoxy vitrimer resins, inspection and health monitoring, as well as innovative and digital processing techniques are objectives for this eight-partner EU project.

Read MoreReSComp Engineering is spun off from University of Padova

Newly founded company is leveraging decades of research and patented methodologies to deliver innovative solutions for composite reliability and structural health monitoring.

Read MorePLEIADES project targets automated induction welding, vitrimeric formulations and digital supply chain

EU-founded project is supporting composite technology advancement for aerospace via automated manufacturing, integrated sensing, novel composite materials development and digital transformation.

Read MoreIn-situ composites sensors for increased production rates, smart processes and life cycle monitoring

Com&Sens FBG sensors are embedded into pressure vessels, rudders and bridges, with new edge and surface connection technology, aimed at cost-effective serial production and monitoring of composite structures.

Ginger Gardiner

Senior Technical Editor, CompositesWorld

Touch Sensity develops SHM tool for hydrogen tanks

Based on its SensityTech technology, the sensor-less system provides a reliable and quick overview of a material’s internal state, detecting and anticipating future critical damage.

Read MoreMORPHO advances structural prognostics, health monitoring and composites manufacturing efficiencies

EU project concluded in January 2025, delivering on its goals to enhance aerospace industry performance and sustainability through real-time monitoring, intelligent control systems and innovative recycling techniques.

Read MoreESA-backed CASSANDRA project targets composite SHM, repair maturation

The CASSANDRA project, joined by CompPair, Com&Sens and CSEM, will support the integration of sophisticated SHM and healing systems into composite structures, driving Europe’s space exploration and technology development efforts.

Read MoreEOLIAN kicks off bio-based wind blade development

EU project will develop bio-based, repairable and recyclable vitrimer composites and advanced sensors for highly reliable, sustainable wind blades.

Read MoreAcellent SHM 4.0 software supports real-time composites monitoring

Integrity and condition of a variety of metal and composite parts and structures is made possible through end-to-end software suites.

Read MoreAcellent contracted to supply SHM systems for KAI KF-21 aircraft

Adaptable custom structural health monitoring (SHM) technology will be used to monitor damage and load of composite aerostructures.

Read More21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

Read MoreINFINITE consortium tackles wireless sensor integration for life-long aircraft monitoring

Engineers from University of Sheffield AMRC will support the embedding of highly specific sensors into composite aerospace structures for MHM and SHM and recylability opportunities.

Read MoreUniversity of Sheffield researchers to drive structural health monitoring in U.K. infrastructure

The £7.7 million program, ROSEHIPS, anticipates exploitation of machine learning, sensing and digital twin technology for automated health monitoring in infrastructure, such as bridges, telecoms masts and wind turbines.

Read MoreNASA selects universities for space station research opportunities

Five universities were chosen for grants to design research experiments that will be conducted on the International Space Station. Initiatives such as robotic surgery and SHM using piezoelectric sensors will be realized.

Read MoreB&T Composites joins R&D project to develop novel composite hydrogen storage tanks

As part of the Greece-based H2Cat project, the company says new tanks will be developed and studied with embedded structural health monitoring (SHM) sensors.

Read MoreFirefly Inspect drone outfitted with infrared vision and AI to transform wind turbine, aircraft inspection

Drone technology combined with active thermography reported to offers faster, cheaper and more in-depth inspection of composites used in wind turbine blades and aircraft wings.

Read MoreMistras receives patent for Sensoria wind blade monitoring technology

The remote rotor blade monitor offers edge-to-edge intelligence that detects and reports damage in real time, enabling better-informed wind blade integrity management.

Read MoreDITF develops textile sensors for composites

German Institutes of Textile and Fiber Research are advancing large-area sensors that can detect deformations and stress using printing onto textiles which are then incorporated into composite structures.

Read MoreDeveloping next-gen, smart engine composite fan blades

EU-funded MORPHO project will use embedded sensors, data-driven hybrid twins and machine learning to increase RTM yield, improve damage-tolerant design, achieve SHM and 100% recycling.

Read MoreAirline safety center departs Sandia Labs for WSU-NIAR

The 30-year Federal Aviation Administration Airworthiness Assurance Center (AANC) program is to combine its knowledge of structural repair, advanced materials and other technologies with a long-standing FAA center at WSU.

Read MoreGerman composite specialist INVENT collaborates in SUSTAINair for increased aircraft circularity

Three-and-a-half-year, 11-partner EU project will include metals and composites spanning design, manufacturing, maintenance, repair, assembly and recycling.

Read MoreShift2Rail issues call for molding tools to produce composite door, interiors demonstrators

Tenders for molding tools in EU project to manufacture composites using compression molding process or equivalent due by April 22, 2021.

Read More